MAC/GMC 4.0 Example Manual

MAC/GMC 4.0 User’s Manual

Volume 3:

Example Problem Manual

Brett A. Bednarcyk

Steven M. Arnold

Example 1a: Effective Properties of a Composite

Example 1b: Effective Properties of a Laminate

Example 1c: Tensile Response of Monolithic Ti-21S

Example 1d: Tensile/Thermal Response of SiC/Ti-21S

Section 2 : Constituent Materials

Example 2a: Bodner-Partom Viscoplastic Constitutive Model

Example 2b: Strain-Rate Dependence of Ti-21S

Example 2c: Incremental Plasticity

Example 2d: Shape Memory Alloy (SMA)

Example 2e: User-Defined Material Properties – Input File

Example 2f: User-Defined Material Properties – USRFUN

Example 2g: User-Defined Material Constitutive Model

Example 2h: External Material Database

Section 3 : Analysis Type and Architecture

Example 3a: Doubly Periodic GMC Internal RUC Library

Example 3b: Doubly Periodic RUC Library with Interface

Example 3c: User-Defined Doubly Periodic Architecture

Example 3d: Triply Periodic GMC Internal RUC Library

Example 3e: User-Defined Triply Periodic GMC Architecture

Example 3f: High-Fidelity Generalized Method of Cells

Example 3g: Laminate Theory – Single Ply

Example 3h: Cross-Ply and Quasi-Isotropic Laminates

Example 3i: Asymmetic Laminate

Example 4a: MAC/GMC Internal Loading Options

Example 4b: SiC/Ti-21S Composite with Residual Stresses

Example 4c: General loading for RUC analysis

Example 4d: Internal Loading Options for Laminate

Example 4e: General loading Option for Laminates

Example 4f: RUC Yield Surface Analysis

Example 4g: Laminate Yield Surface Analysis

Example 4h: Predictor-Corrector Time Integration

Section 5 : Damage and Failure

Example 5a: Composite Allowables Calculation

Example 5b: Subcell Static Failure Analysis

Example 5c: Laminate Static Failure Analysis

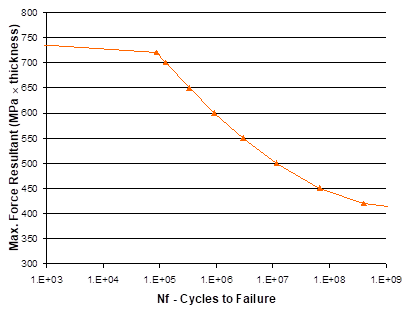

Example 5d: Fatigue Damage Analysis

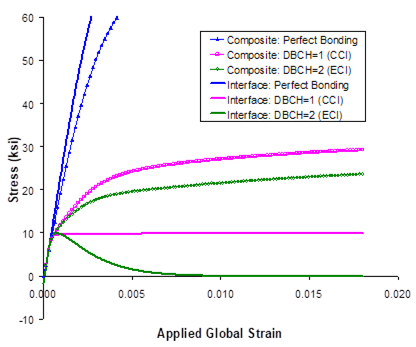

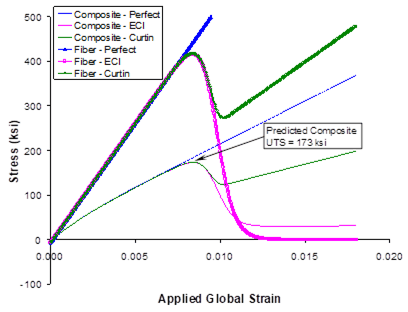

Example 5e: Fiber-Matrix Debonding

Section 6 : Output and Data Visualization

Example 6b: PATRAN Post-Processing

Example 6c: MATLAB Post-Processing

Example 7a: Implicitly Integrated Multimechanism GVIPS

Example 7b: Electromagnetic RUC Analysis

Example 7c: Electromagnetic Laminate Analysis

Example 7d: Woven Composite Analysis – Single Step

Example 7e: Woven Composite Analysis – Two Step

Complete output file for Example 1a

usrfun.F90: User-defined material property function file

usrmat.F90: User-defined material constitutive model file

usrformde.F90: User-defined stiffness matrix calculation file

This document is the third volume in the three volume set of User’s Manuals for the Micromechanics Analysis Code with Generalized Method of Cells Version 4.0 (MAC/GMC 4.0). Volume 1 is the Theory Manual, Volume 2 is the Keywords Manual, and this document is the Example Problems Manual.

MAC/GMC 4.0 is composite material and laminate analysis software developed at the NASA Glenn Research Center. It is based on the generalized method of cells (GMC) micromechanics theory (Paley and Aboudi, 1992), which provides access to the local stress and strain fields in the composite material. This access grants GMC the ability to accommodate arbitrary local models for inelastic material behavior and various types of damage and failure. The MAC/GMC 4.0 software package has been built around GMC to provide the theory with a user-friendly framework, along with a library of local inelastic, damage, and failure models. Further, application of simulated thermo-mechanical loading, generation of output results, and selection of architectures to represent the composite material, have been automated in MAC/GMC 4.0. Finally, classical lamination theory has been implemented within MAC/GMC 4.0 wherein GMC is used to model the composite material response of each ply. Thus, the full range of GMC composite material capabilities is available for analysis of arbitrary laminate configurations as well. Although the focus of previous versions of MAC/GMC has been on metallic based composites (due to the need for inelastic constitutive models for the metallic matrix), the code is fully capable of analyzing polymeric and ceramic based composites as well.

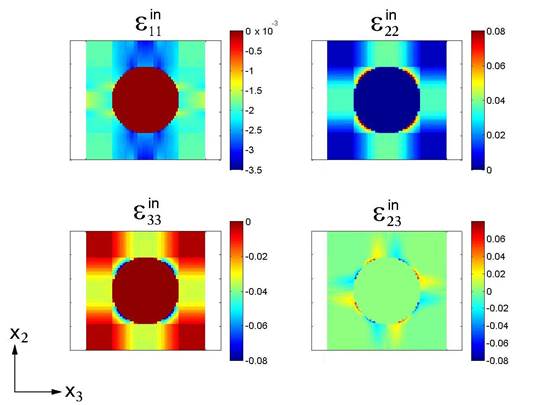

The many new features incorporated within version 4.0 of the MAC/GMC software are enumerated in the MAC/GMC 4.0 Keywords Manual Introduction. The two most important new features, from the standpoint of analysis capabilities are: 1) the ability to model electromagnetic (“smart”) composites and laminates, and 2) the incorporation of the new high-fidelity generalized method of cells (HFGMC) micromechanics theory. Electromagnetic materials and structures are those that are capable of responding electrically or magnetically to imposed thermo-mechanical loads and responding mechanically to imposed electrical or magnetic loads. These so-called “smart” materials have potential to enable the next generation of multi-functional structures that can automatically sense and react to various stimuli. Example Problems 7b and 7c illustrate the usage of the MAC/GMC 4.0 electromagnetic capabilities. The HFGMC micromechanics theory involves a formulation that enables the micromechanics model to be significantly more accurate in its predicted local stress and strain fields compared to GMC. Because this improved accuracy naturally places additional computation demands on the MAC/GMC 4.0 code, the code may now be considered to have variable fidelity. When computational efficiency is at a premium, the standard GMC micromechanics capabilities can be employed. Conversely, when local filed accuracy is more important, the HFGMC micromechanics capabilities can be employed. Example Problem 3f presents the usage of the HFGMC capabilities of MAC/GMC 4.0.

Format of this Manual

It is the objective of this manual to illustrate, through example, how to use the MAC/GMC 4.0 software. Forty-three individual example problems are presented that describe the usage of most of the code’s capabilities. The manual is broken into seven sections. The first section presents four basic examples that outline the fundamental procedures used to execute MAC/GMC 4.0 simulations. For new users of MAC/GMC, the first step towards learning to use the code should be gaining a good understanding of these basic examples. Section 7 deals with advanced topics. Sections 2 – 6 contain examples that highlight particular capabilities of the code.

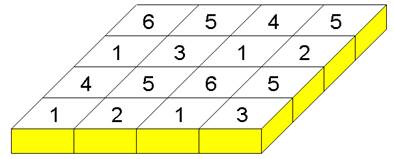

The execution of MAC/GMC 4.0 is controlled by an ASCII input file that contains a number of keywords and specifiers. The keywords can be broken into groups that are related to particular capabilities of the code. The MAC/GMC 4.0 Keywords are listed with their associated groups and applicable example problems in Table I.1. These twenty-two keywords control all aspects of the MAC/GMC 4.0 execution. Each is described in detail in the MAC/GMC 4.0 Keywords Manual. The examples presented in Sections 2 – 6 in this MAC/GMC 4.0 Example Problems Manual illustrate capabilities that correspond to the keyword groups 2 – 6 given in Table I.1.

Table I.1 MAC/GMC 4.0 keywords and their associated example problems. The problems that specifically highlight a particular keyword are hyperlinked (typed in blue and underlined).

|

1) Flag-Type Keywords |

|

|

*CHECK |

None |

|

*CONDUCTIVITY |

|

|

*ELECTROMAG |

|

|

2) Material Keywords |

|

|

*MDBPATH |

|

|

*CONSTITUENTS |

All example problems (required keyword) Section 2 Examples

|

|

3) Analysis Type and Architecture Keywords |

|

|

*RUC |

Examples 1a, 1c, 1d, 2a-h, 3a, 3b, 3c, 3d, 3e, 3f, 4a-c, 4f, 4h, 5a, 5b, 5d-f, 6a-c, 7a, 7b, 7d |

|

*LAMINATE |

Examples 1b, 3g, 3h, 3i, 4d, 4e, 4g, 5c, 5d, 6c, 7c

|

|

4) Loading Keywords |

|

|

*MECH |

Examples 1c, 1d, 2a-h, 3a-i, 4a, 4b, 4c, 4d, 4e, 4h, 5b-f, 6a, 6b, 7a-c |

|

*THERM |

Examples 1d, 2e-h, 3a, 3b, 3d-i, 4a, 4b-f, 4h, 5b-f, 6a-c, 7a-c |

|

*SOLVER |

Examples 1c, 1d, 2a, 2b, 2c-h, 3a-e, 3f-i, 4a, 4b-f, 4h, 5b-f, 6a-c, 7a-c |

|

*SURF |

Examples 4f, 4g

|

|

5) Damage and Failure Keywords |

|

|

*ALLOWABLES |

|

|

*FAILURE_SUBCELL |

|

|

*FAILURE_CELL |

|

|

*DAMAGE |

|

|

*DEBOND |

|

|

*CURTIN |

|

|

6) Results and Data Output Keywords |

|

|

|

All example problems |

|

*XYPLOT |

|

|

*PATRAN |

|

|

*MATLAB |

Examples 3f, 6c

|

|

7) End of File Keyword |

|

|

*END |

All example problems (required keyword)

|

Each example problem presented in this manual is associated with a MAC/GMC 4.0 example problem input file (all of which are distributed with the MAC/GMC 4.0 software). A general description is given for each example problem, followed by a listing of the input file for that example problem. An “Annotated Input Data” section is given for each example problem that describes the meaning and purpose of each line of data within the input file. Finally, the results of the example problems are presented and discussed. The user should be able to reproduce these results using the provided MAC/GMC 4.0 example problem input files, upon successful installation of the software package.

This Example Problem Manual is heavily cross-referenced to the MAC/GMC 4.0 Keywords Manual (which gives an in-depth description of each keyword) and the MAC/GMC 4.0 Theory Manual (which presents the mathematical models upon which the MAC/GMC 4.0 code is based). Throughout the Example Problem Manual, when the annotated input data associated with a particular keyword is given, a cross-reference to the Section # in the MAC/GMC 4.0 Keywords Manual is given as: “[KM_#]”.

In this first section, four basic MAC/GMC 4.0 example problems are presented that introduce many of the fundamental concepts associated with the code. Examples that appear in the subsequent sections of this manual rely on the user’s knowledge and understanding of these basic concepts, and they also borrow from the basic problem configurations represented by these four examples. The first two example problems do not involve applied loading as the code is used only to determine effective properties for a composite and a laminate. The subsequent two problems involve application of mechanical and thermal loading on a monolithic metallic alloy and a composite in which the same alloy serves as the matrix material.

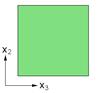

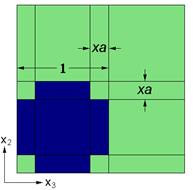

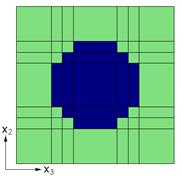

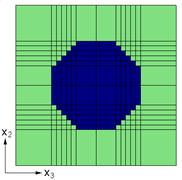

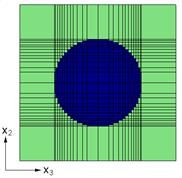

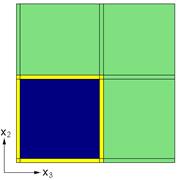

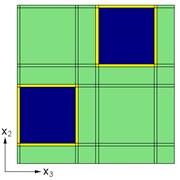

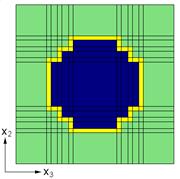

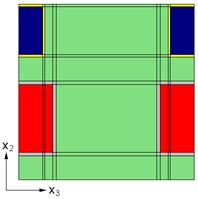

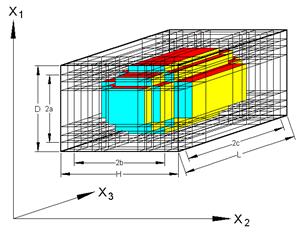

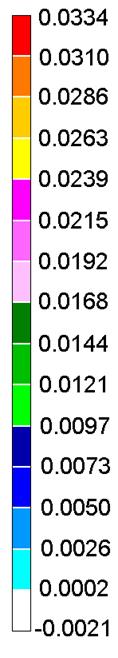

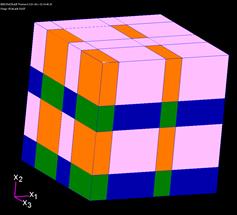

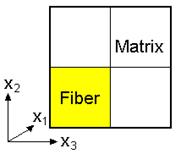

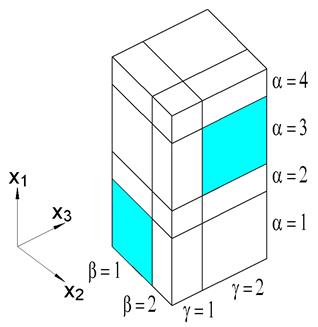

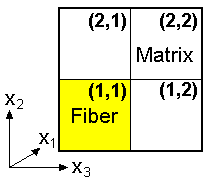

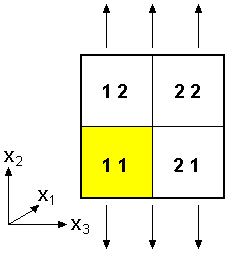

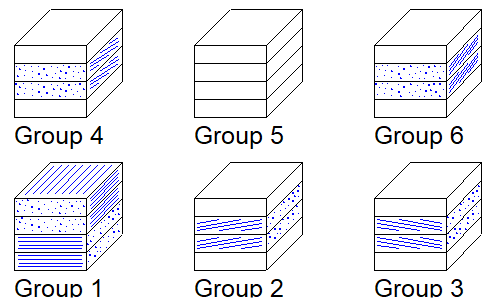

This example problem determines the effective thermal and mechanical properties of a continuous graphite fiber/epoxy matrix composite material. The simplest repeating unit cell (RUC) available within MAC/GMC 4.0 that can represent the architecture of this composite, namely a 2´2 RUC (see Figure 1.1), is employed. As Figure 1.1 shows, the doubly periodic RUC consists of four subcells in the x2-x3 plane, one of which represents the fiber and three of which represent the matrix. The term “doubly periodic” indicates that the RUC repeats infinitely in the two in-plane (x2-x3) directions and is infinite in the out-of-plane (continuously reinforced, x1) direction. The RUC thus represents a continuum (as opposed to a structure with boundaries). Based on the properties and arrangement of the fiber and matrix constituents, MAC/GMC 4.0 uses the doubly periodic generalized method of cells (GMC) theory to homogenize the composite material and determine the effective (anisotropic) properties of this continuously reinforced homogenized material. The constituent material properties in this problem are temperature-independent and are read from the MAC/GMC input file.

Figure 1.1 MAC/GMC 4.0 2´2 doubly periodic repeating unit cell.

MAC/GMC Input File: example_1a.mac

MAC/GMC 4.0 Example 1a - graphite/epoxy effective properties

*CONDUCTIVITY

NTEMP=1 TEMP=21.

*CONSTITUENTS

NMATS=2

# -- Graphite fiber

M=1 CMOD=6 MATID=U MATDB=1 &

EL=388.2E9,7.6E9,0.41,0.45,14.9E9,-0.68E-6,9.74E-6

K=500.,10.

# -- Epoxy matrix

M=2 CMOD=6 MATID=U MATDB=1 &

EL=3.45E9,3.45E9,0.35,0.35,1.278E9,45.E-6,45E-6

K=0.19,0.19

*RUC

MOD=2 ARCHID=1 VF=0.65 F=1 M=2

NPL=-1

*END

F Note: The lines of the input file starting with the “#” character are comments and thus ignored by the code.

Annotated Input Data

1) Flags:

a) Determine effective thermal conductivity properties (*CONDUCTIVITY) [KM_1]:

NTEMP=1 TEMP=21.

Number of conductivity temps: 1 (NTEMP=1)

Conductivity temps: 21. (TEMP=21.)

*CONDUCTIVITY is a flag-type keyword that indicates to MAC/GMC 4.0 that effective thermal conductivities should be calculated. The thermal conductivity calculation can be performed at any desired temperature (specified by NTEMP= and TEMP=). This feature is useful when the constituent properties (specified under *CONSTITUENTS) are temperature-dependent. In this example problem, the material properties are temperature-independent, so even if additional conductivity temperatures were specified, the calculated effective thermal conductivities would be the same for each temperature. Note that, in the presence of the *CONDUCTIVITY keyword, thermal conductivities for the constituent materials must be specified under *CONSTITUENTS.

2) Constituent materials (*CONSTITUENTS) [KM_2]:

NMATS=2

# -- Graphite fiber

M=1 CMOD=6 MATID=U MATDB=1 &

EL=388.2E9,7.6E9,0.41,0.45,14.9E9,-0.68E-6,9.74E-6

K=500.,10.

# -- Epoxy matrix

M=2 CMOD=6 MATID=U MATDB=1 &

EL=3.45E9,3.45E9,0.35,0.35,1.278E9,45.E-6,45.E-6

K=0.19,0.19

Number of materials: 2 (NMATS=2)

Constitutive models: Elastic (CMOD=6)

Materials: User-defined (Graphite) (MATID=U)

User-defined (Epoxy) (MATID=U)

Material property source: Read from input file (MATDB=1)

Material properties: See Table 1.1 (EL=… and K=…)

Table 1.1 Constituent material properties for example 1a.

|

|

EA (GPa) |

ET (GPa) |

nA |

nT |

GA (GPa) |

aA (10-6/ °C) |

aT (10-6/ °C) |

kA (W/mK) |

kT (W/mK) |

|

Graphite |

388.2 |

7.6 |

0.41 |

0.45 |

14.9 |

-0.68 |

9.74 |

500. |

10. |

|

Epoxy |

3.45 |

3.45 |

0.35 |

0.35 |

1.278 |

45. |

45. |

0.19 |

0.19 |

This example problem employs user-defined material properties. In the present case of elastic material constitutive behavior (as specified by CMOD=6), the temperature-independent elastic properties and coefficients of thermal expansion (CTEs) are simply listed as EL=EA, ET, nA, nT, GA, aA, aT (axial and transverse elastic modulus, axial and transverse Poisson ratio, axial shear modulus, and axial and transverse CTE, respectively). The temperature-independent thermal conductivities are specified on a separate line as K=kA, kT (axial and transverse thermal conductivity, respectively). Note that, while the K=… specification is required when the *CONDUCTIVITY keyword is present, in the absence of *CONDUCTIVITY, K=… should be omitted. In addition, the employed elastic constitutive model (CMOD=6) allows for transversely isotropic material properties. That is, it allows for specification of different properties in the axial and transverse direction (as specified for the graphite fiber, for example). Care should be exercised, however, as CMOD=6 requires that the axial direction be associated with the x1-axis (see Figure 1.1). For transversely isotropic elastic constituent behavior with axes other than the x1-axis, constitutive model 9 (CMOD=9) can be employed (see Keywords Manual Section 2). The isotropic simplification of the employed elastic model (CMOD=6) is obtained by setting EA = ET = E, nA = nT = n, GA = E/2(1+n) = G, aA = aT = a, and kA = kT.

In addition to direct specification of the constituent material properties within the MAC/GMC 4.0 input file, several other options exist for material property specification. These are: material properties taken from the code’s internal database, material properties read from an external database, and material properties determined from the user-defined subroutine (usrfun.F90). Also, for different constitutive models (specified by CMOD=), and for temperature-dependent properties, the input requirements are different. These options and requirements are described in Section 2 of the MAC/GMC 4.0 Keywords Manual, and example problems involving these options and requirements are presented in Section 2 of this Example Problem Manual.

The units of the material properties employed by MAC/GMC 4.0 are arbitrary. However, the units must be consistent in order for the MAC/GMC 4.0 results to be meaningful. It is the user’s responsibility to ensure that the constituent material property units are consistent. This is particularly important when employing constituent materials from the internal material property database. For more information on constitutive material property units, see the MAC/GMC 4.0 Keywords Manual Section 2.

3) Analysis type (*RUC) ® Repeating Unit Cell Analysis [KM_3]:

MOD=2 ARCHID=1 VF=0.65 F=1 M=2

Analysis model: Doubly periodic GMC (MOD=2)

RUC architecture: square fiber, square pack (ARCHID=1)

Fiber volume fraction: 0.65 (VF=0.65)

Material assignment: graphite fiber (F=1)

epoxy matrix (M=2)

By including *RUC within the input file, repeating unit cell analysis, which represents a continuum has been selected. In this example, a repeating unit cell architecture is selected from the MAC/GMC internal library by specifying ARCHID=1. This RUC, which is the simplest representation of a continuous fiber composite, is shown in Figure 1.1. The additional information required for this RUC architecture is the fiber volume fraction and which of the two constituent materials occupy the subcells associated with the fiber (F=) and the matrix (M=). Based on the specified fiber volume fraction, MAC/GMC 4.0 determines the dimensions of each subcell. Then, given the information on which materials occupy which subcells, the code has obtained all of the data (the constituent properties and their arrangement) required to homogenize the composite and determine its effective properties via the generalized method of cells theory.

F Note: While only VF=, F=, and M= are required for ARCHID=1, other RUC architectures contained within the MAC/GMC 4.0 RUC architecture library require unique input data. Example problems dealing with other RUC architectures are presented within Section 3 of this Example Manual. For additional information on RUC architectures, see the MAC/GMC 4.0 Keywords Manual Section 3.

4) Loading: None

As stated earlier, this example problem involves determining effective properties only. Therefore, no simulated thermal or mechanical loading need be specified. See Example Problem 1c for an introduction on specifying applied loading histories.

5) Damage and Failure: None

6) Output:

a) Output file print level (*PRINT) [KM_6]:

NPL=-1

Print level: -1 (effective properties only) (NPL=-1)

The print level generally indicates how much information will be written to the output file. A level of 0 prints the least amount of information while a level of 10 prints the most. In addition, a special case of NPL=-1 indicates that the code should execute only to determine effective properties (as opposed to determining the response to simulated applied loading). See the MAC/GMC 4.0 Keywords Manual Section 6 for details on the various print levels.

F Note: If NPL≠-1 at least one of the keywords *MECH and *THERM must be present in the input file.

b) x-y plots (*XYPLOT): None

Because no simulated mechanical loading is applied in the present example, no x-y plot data will be written to output files. See Example Problem 1c for an introduction to generating x-y plots.

7) End of file keyword: (*END)

The *END end of file keyword must be included in all MAC/GMC 4.0 input files.

Results

In this example problem, since MAC/GMC 4.0 is employed only to determine the effective properties of the graphite/epoxy composite, all results are contained within the output file. Recall that (as described in the Keywords Manual), if the code is executed using the command:

mac4 example_1a

then the relevant output is written to the ASCII file example_1a.out. The entirety of this output file is provided in the appendix, and the results given below were taken directly from this output file.

The results include the effective thermal conductivities of the 0.65 fiber volume fraction graphite/epoxy composite, the effective stiffness matrix (CG), the inverse of the effective compliance matrix (CI), the effective engineering moduli (i.e., effective elastic properties), and the effective coefficients of thermal expansion. Recall from Figure 1.1 that the axial fiber direction is associated with the x1-axis, while the x2 and x3 directions are transverse to the continuous fiber. The high thermal conductivity, high stiffness, and low CTE associated with the axial direction of the fiber constituent are evident in the effective properties of the composite associated with the x1 direction. Transverse to the fiber direction, on the other hand, the thermal conductivity and stiffness are low while the CTE is high.

-------------------------------------------------

Effective Thermal Conductivities

At Temperature = 21.0

K11 = 325.0665

K22 = 0.7694

K33 = 0.7694

-------------------------------------------------

--------------------- EFFECTIVE PROPERTIES AT TEMPERATURE = 21.00 ----------------------------

CG - Effective/Macro Stiffness Matrix

0.2571E+12 0.4500E+10 0.4500E+10

0.4500E+10 0.7828E+10 0.3707E+10

0.4500E+10 0.3707E+10 0.7828E+10

0.1916E+10

0.4166E+10

0.4166E+10

CI - Effective/Macro Compliance Matrix

0.3944E-11 -0.1539E-11 -0.1539E-11

-0.1539E-11 0.1653E-09 -0.7738E-10

-0.1539E-11 -0.7738E-10 0.1653E-09

0.5219E-09

0.2400E-09

0.2400E-09

Effective Engineering Moduli

E11S= 0.2535E+12

N12S= 0.3901

E22S= 0.6050E+10

N23S= 0.4682

E33S= 0.6050E+10

G23S= 0.1916E+10

G13S= 0.4166E+10

G12S= 0.4166E+10

Effective Thermal Expansion Coefficients

-0.4724E-06 0.2663E-04 0.2663E-04

------------------------------------------------------------------------------------------------

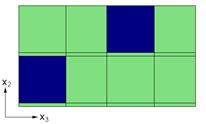

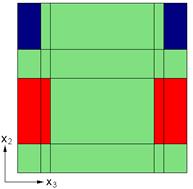

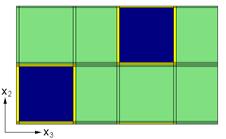

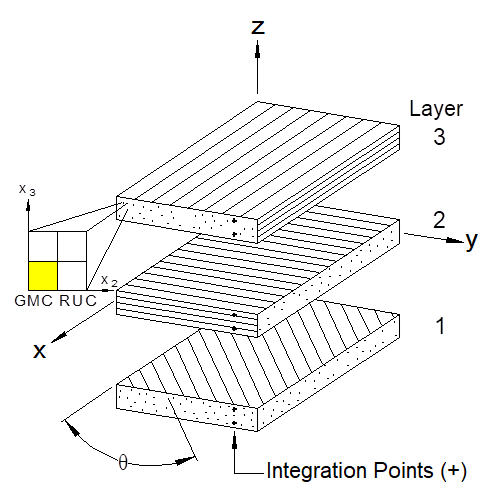

This example problem, like Example 1a, involves only determination of effective properties rather than determination of the response to an applied loading history. This problem, however, involves a cross-ply [90°/0°]s graphite/epoxy laminate rather than a unidirectional graphite/epoxy composite. Since the constituent materials are the same, the difference between the input files in this and the previous example problem amounts to replacing the *RUC keyword with the *LAMINATE keyword. While the *RUC keyword specified analysis of a continuum in Example 1a, in the present example the *LAMINATE keyword specifies analysis of the laminated plate structure (as modeled using lamination theory).

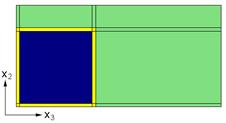

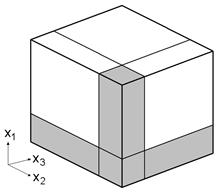

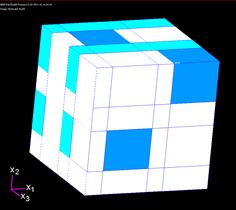

The geometry and coordinate system employed in the code for the laminate is shown in Figure 1.2. The global x-y-z coordinate system is applicable to the laminate as a whole, while the local coordinates (x1-x2-x3) apply within each layer. As shown, locally, each layer is modeled using a GMC RUC analysis.

Figure 1.2 General laminate geometry and coordinate system employed in MAC/GMC 4.0. The local behavior of each layer is modeled using a generalized method of cells (GMC) repeating unit cell (RUC) analysis.

MAC/GMC Input File: example_1b.mac

MAC/GMC 4.0 Example 1b - graphite/epoxy laminate

*CONSTITUENTS

NMATS=2

# -- Graphite fiber

M=1 CMOD=6 MATID=U MATDB=1 &

EL=388.2E9,7.6E9,0.41,0.45,14.9E9,-0.68E-6,9.74E-6

# -- Epoxy matrix

M=2 CMOD=6 MATID=U MATDB=1 &

EL=3.45E9,3.45E9,0.35,0.35,1.278E9,45.E-6,45E-6

*LAMINATE

NLY=3

LY=1 MOD=2 THK=0.25 ANG=90 ARCHID=1 VF=0.65 F=1 M=2

LY=2 MOD=2 THK=0.50 ANG=0 ARCHID=1 VF=0.65 F=1 M=2

LY=3 MOD=2 THK=0.25 ANG=90 ARCHID=1 VF=0.65 F=1 M=2

NPL=-1

*END

Annotated Input Data

1) Flags: None

2) Constituent materials (*CONSTITUENTS) [KM_2]:

Number of materials: 2 (NMATS=2)

Constitutive models: Elastic (CMOD=6)

Materials: User-defined (Graphite) (MATID=U)

User-defined (Epoxy) (MATID=U)

Material property source: Read from input file (MATDB=1)

Material properties: See Table 1.1 (EL=… and K=…)

This example problem employs the same user-defined material properties as in Example 1a.

3) Analysis type (*LAMINATE) ® Laminate Analysis [KM_3]:

NLY=3

LY=1 MOD=2 THK=0.25 ANG=90 ARCHID=1 VF=0.65 F=1 M=2

LY=2 MOD=2 THK=0.50 ANG=0 ARCHID=1 VF=0.65 F=1 M=2

LY=3 MOD=2 THK=0.25 ANG=90 ARCHID=1 VF=0.65 F=1 M=2

Number of layers: 3 (NLY=3)

|

Layer |

Analysis Model |

Thickness |

Fiber Angle |

Architecture |

Volume fraction |

Fiber material |

Matrix material |

|

(LY=) |

(MOD) |

(THK) |

(ANG) |

(ARCHID) |

(VF) |

(F) |

(M) |

|

1 |

GMC-2D |

0.25 |

90° |

square fiber, square pack |

0.65 |

graphite |

epoxy |

|

2 |

GMC-2D |

0.50 |

0° |

square fiber, square pack |

0.65 |

graphite |

epoxy |

|

3 |

GMC-2D |

0.25 |

90° |

square fiber, square pack |

0.65 |

graphite |

epoxy |

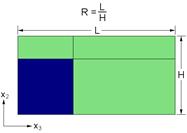

Because the local behavior of each layer is represented by a GMC repeating unit cell, information similar to that specified under *RUC (in Example 1a) is now specified for each layer. Here, each layer is represented as the same unidirectional graphite/epoxy composite whose effective properties were determined in Example 1a. In addition, for each layer, the thickness (THK) and angle (ANG) in degrees must be specified. The thicknesses of the layers is important not only to provide the dimensions of the layers with respect to each other, but also to provide the overall thickness of the laminate. This overall thickness is important to the calculation of the laminate force and moment resultants during simulated applied loading. The angle specifies the orientation of each layer’s local coordinate system relative to the laminate (global coordinate system). Note that the middle layer’s thickness is twice that of the outer layers, resulting in a layup equivalent to four equal thickness layers.

Example problems dealing with other laminate configurations are presented within Section 3 of this Example Manual. For additional information on the code’s laminate analysis capabilities, see the MAC/GMC 4.0 Keywords Manual Section 3 and the MAC/GMC 4.0 Theory Manual Section 3.

4) Loading: None

5) Damage and Failure: None

6) Output:

a) Output file print level (*PRINT) [KM_6]:

NPL=-1

Print level: -1 (effective properties only) (NPL=-1)

b) x-y plots (*XYPLOT): None

7) End of file keyword: (*END)

Results

As in Example problem 1a, the results of this example are contained solely within the output file because only effective properties (as opposed to the response to applied loading) are determined. The lines below are taken directly from the output file. From the GMC repeating unit cell analysis of each layer, the effective stiffness matrix (CG), the effective compliance matrix (CI), the effective engineering moduli, and the effective CTEs are output (in local coordinates). Then, from the lamination theory analysis, the laminate axial stiffness (A), coupling stiffness (B), and bending stiffness (D) matrices are determined, as are the effective laminate engineering constants. Examining these results, it is clear that (in the local coordinates of each layer) the effective properties of each layer are identical to each other and the unidirectional composite results from Example 1a. The laminate results show that, for this symmetric cross-ply laminate, there is no coupling between extension and bending (B matrix is zero) and the laminate normal and shear behavior is decoupled (A16, A26, D16, and D26 are close to zero). Finally, the effective (apparent) elastic moduli of the laminate in the x and y directions are identical as expected.

--------------------- EFFECTIVE PROPERTIES AT TEMPERATURE = 21.00 ----------------------------

* FOR LAYER NUMBER 1 *

CG - Effective/Macro Stiffness Matrix

0.2571E+12 0.4500E+10 0.4500E+10

0.4500E+10 0.7828E+10 0.3707E+10

0.4500E+10 0.3707E+10 0.7828E+10

0.1916E+10

0.4166E+10

0.4166E+10

CI - Effective/Macro Compliance Matrix

0.3944E-11 -0.1539E-11 -0.1539E-11

-0.1539E-11 0.1653E-09 -0.7738E-10

-0.1539E-11 -0.7738E-10 0.1653E-09

0.5219E-09

0.2400E-09

0.2400E-09

Effective Engineering Moduli

E11S= 0.2535E+12

N12S= 0.3901

E22S= 0.6050E+10

N23S= 0.4682

E33S= 0.6050E+10

G23S= 0.1916E+10

G13S= 0.4166E+10

G12S= 0.4166E+10

Effective Thermal Expansion Coefficients

-0.4724E-06 0.2663E-04 0.2663E-04

--------------------- EFFECTIVE PROPERTIES AT TEMPERATURE = 21.00 ----------------------------

* FOR LAYER NUMBER 2 *

CG - Effective/Macro Stiffness Matrix

0.2571E+12 0.4500E+10 0.4500E+10

0.4500E+10 0.7828E+10 0.3707E+10

0.4500E+10 0.3707E+10 0.7828E+10

0.1916E+10

0.4166E+10

0.4166E+10

CI - Effective/Macro Compliance Matrix

0.3944E-11 -0.1539E-11 -0.1539E-11

-0.1539E-11 0.1653E-09 -0.7738E-10

-0.1539E-11 -0.7738E-10 0.1653E-09

0.5219E-09

0.2400E-09

0.2400E-09

Effective Engineering Moduli

E11S= 0.2535E+12

N12S= 0.3901

E22S= 0.6050E+10

N23S= 0.4682

E33S= 0.6050E+10

G23S= 0.1916E+10

G13S= 0.4166E+10

G12S= 0.4166E+10

Effective Thermal Expansion Coefficients

-0.4724E-06 0.2663E-04 0.2663E-04

--------------------- EFFECTIVE PROPERTIES AT TEMPERATURE = 21.00 ----------------------------

* FOR LAYER NUMBER 3 *

CG - Effective/Macro Stiffness Matrix

0.2571E+12 0.4500E+10 0.4500E+10

0.4500E+10 0.7828E+10 0.3707E+10

0.4500E+10 0.3707E+10 0.7828E+10

0.1916E+10

0.4166E+10

0.4166E+10

CI - Effective/Macro Compliance Matrix

0.3944E-11 -0.1539E-11 -0.1539E-11

-0.1539E-11 0.1653E-09 -0.7738E-10

-0.1539E-11 -0.7738E-10 0.1653E-09

0.5219E-09

0.2400E-09

0.2400E-09

Effective Engineering Moduli

E11S= 0.2535E+12

N12S= 0.3901

E22S= 0.6050E+10

N23S= 0.4682

E33S= 0.6050E+10

G23S= 0.1916E+10

G13S= 0.4166E+10

G12S= 0.4166E+10

Effective Thermal Expansion Coefficients

-0.4724E-06 0.2663E-04 0.2663E-04

----------------------- LAMINATE RESULTS AT TEMPERATURE = 21.00 -------------------------------

Laminate Axial Stiffness Matrix [A]

1.303E+11 2.369E+09 -4.748E-01

2.369E+09 1.303E+11 -2.500E+01

-4.748E-01 -2.500E+01 4.166E+09

Laminate Coupling Stiffness Matrix [B]

0.000E+00 0.000E+00 0.000E+00

0.000E+00 0.000E+00 0.000E+00

0.000E+00 0.000E+00 0.000E+00

Laminate Bending Stiffness Matrix [D]

3.093E+09 1.974E+08 -6.924E-02

1.974E+08 1.862E+10 -3.646E+00

-6.924E-02 -3.646E+00 3.472E+08

Laminate Engineering Constants (only valid for symmetric laminates)

Exx= 1.302E+11

Nxy= 1.819E-02

Eyy= 1.302E+11

Gxy= 4.166E+09

This example problem demonstrates MAC/GMC’s capability to apply a loading history to a material and determine the response. For the sake of simplicity, the analyzed material is not a composite, but rather simply a monolithic titanium alloy commonly used in metal matrix composites; Ti-21S. Unlike the previous examples, the material properties for the Ti-21S are taken from the code’s internal material property database. An applied strain of 0.02 (i.e., 2%) is applied to the alloy over 200 seconds (sec.), resulting in an applied strain rate of 10-4/sec. This example illustrates the basic form of a MAC/GMC 4.0 input file involving applied mechanical loading and also could be of interest when the response of a particular constituent material is desired.

MAC/GMC Input File: example_1c.mac

MAC/GMC 4.0 Example 1c - monolithic Ti-21S

*CONSTITUENTS

NMATS=1

M=1 CMOD=4 TREF=23. MATID=A

# M=1 CMOD=4 TREF=650. MATID=A

*RUC

MOD=1 M=1

*MECH

LOP=1

NPT=2 TI=0.,200. MAG=0.,0.02 MODE=1

*SOLVER

METHOD=1 NPT=2 TI=0.,200. STP=1.

NPL=6

*XYPLOT

FREQ=5

MACRO=1

NAME=example_1c X=1 Y=7

MICRO=0

*END

Annotated Input Data

1) Flags: None

2) Constituent materials (*CONSTITUENTS) [KM_2]:

NMATS=1

M=1 CMOD=4 TREF=23. MATID=A

# M=1 CMOD=4 TREF=650. MATID=A

Number of materials: 1 (NMATS=1)

Constitutive model: Isotropic GVIPS (CMOD=4)

Material: Ti-21S (MATID=A)

Reference Temperature: 23. °C (TREF=23.)

The reference temperature for a particular constituent material indicates the temperature at which the code should evaluate the material properties for that material. This overrides the temperature-dependence of a material’s properties and causes the code to use the temperature indicated by TREF no matter what temperature the simulation is at. TREF is also useful, as in the current example, when no thermal loading is included in the simulation. In this case, without TREF, the code would not know at what temperature to take the Ti-21S material properties (and an error would result) since the properties stored for Ti-21S in the internal material database vary with temperature. Note that the temperature units (°C) are dictated by those used in the internal material database, which are always °C.

In addition, the example input file contains the line:

# M=1 CMOD=4 TREF=650. MATID=A

Here, the “#” sign in the first column indicates that this line is a “comment”, i.e., it is ignored by the code when the input file is read. Thus, by uncommenting this line and commenting out the line above, it is possible to execute the exact same case using Ti-21S material properties at 650 °C rather than 23 °C. Results for both of these temperatures are given below.

3) Analysis type (*RUC) ® Repeating Unit Cell Analysis [KM_3]:

MOD=1 M=1

Analysis model: Monolithic material (MOD=1)

Material assignment: Ti-21S (M=1)

By including *RUC within the input file, repeating unit cell analysis, which represents a continuum has been selected. In this example, a monolithic material is analyzed, and the material to be analyzed must be selected from the materials indicated in *CONSTITUENTS.

4) Loading:

a) Mechanical (*MECH) [KM_4]:

LOP=1

NPT=2 TI=0.,200. MAG=0.,0.02 MODE=1

Loading option: 1 (LOP=1)

Number of points: 2 (NPT=2)

Time points: 0., 200. sec. (TI=0.,200.)

Load magnitudes: 0., 0.02 (MAG=0.,0.02)

Loading mode: strain control (MODE=1)

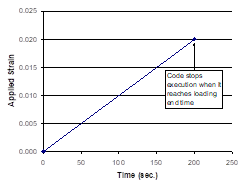

The loading option indicates the direction of the applied mechanical loading (see the MAC/GMC 4.0 Keyword Manual Section 4 for details on the loading options). In this case the mechanical loading is applied in the x1-direction, with all other stress components kept at zero. The mechanical loading profile is specified through time-magnitude pairs that specify the loading history to be applied (the first time must always be zero). In MAC/GMC 4.0, the unit of time is seconds (sec.). Finally, the loading mode indicates whether strains (MODE=1) or stresses (MODE=2) are applied. The applied mechanical load history for this problem is plotted in Figure 1.3.

Figure 1.3 Example 1c: Applied strain vs. time history.

F Note: The applied global strain rate is 0.02 ÷ 200. sec. = 1´10-4/sec.

b) Thermal (*THERM): None

No thermal loading is applied in this example. This necessitates the use of TREF in *CONSTITUENTS to indicate the temperature at which the material properties are taken. If a thermal loading profile were specified, TREF would not be needed (although it could be specified).

c) Time integration (*SOLVER) [KM_4]:

METHOD=1 NPT=2 TI=0.,200. STP=1.

Time integration method: Forward Euler (METHOD=1)

Number of time points: 2 (NPT=2)

Time points: 0., 200. sec. (TI=0.,200.)

Time step size (from 0. – 200. sec.): 1. sec. (STP=1.)

Two explicit methods of time integration are available in MAC/GMC 4.0; Forward Euler (METHOD=1) with a specified time step and Predictor/Corrector (METHOD=2) with a self-adaptive time step size. In this example, the simpler Forward Euler method is employed. The forward Euler time integration is specified by a time point – time step size profile. Since the time step size pertains to a time segment between two time points, there will always be one fewer time step size specified than the number of time points specified. As in *MECH, the first time must always be zero.

5) Damage and Failure: None

6) Output:

a) Output file print level (*PRINT) [KM_6]:

NPL=6

Print level: 6 (NPL=6)

The print level indicates how much information will be written to the output file. A level of 0 prints the least amount of information while a level of 10 prints the most. A print level of 6 results in an intermediate level of writing to the output file including the effective stiffness matrix at each time step. See the MAC/GMC 4.0 Keyword Manual Section 6 for details on the various print levels.

b) x-y plots (*XYPLOT) [KM_6]:

FREQ=5

MACRO=1

NAME=example_1c X=1 Y=7

MICRO=0

Frequency: 5 (FREQ=5)

Number of macro plots: 1 (MACRO=1)

Macro plot name: example_1c (NAME=example_1c)

Macro plot x-y quantities: ε11, σ11 (X=1 Y=7)

Number of micro plots: 0 (MICRO=0)

In this example, a macro (repeating unit cell level) plot file containing the σ11-ε11 stress-strain response is generated as indicated by the macro plot x-y quantities X=1, Y=7 (see the MAC/GMC 4.0 Keyword Manual Section 6 for details on the macro plot x-y quantities). No micro (subcell level) plots are generated. The frequency indicates how often data will be written to the x-y plot data file. In this case, data will be written every 5 time steps (and thus every 5 seconds of the simulated applied loading). The extension “_macro.data” is appended to the indicated macro plot file name, so, in this example, the file “EXAMPLE_1c_macro.data” is written to the path location associated with the input file.

7) End of file keyword: (*END)

Results

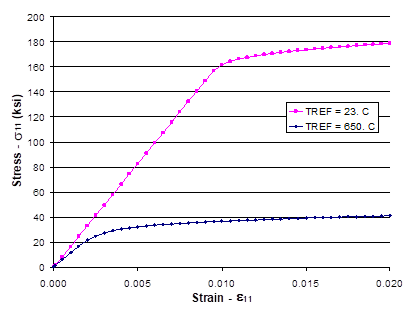

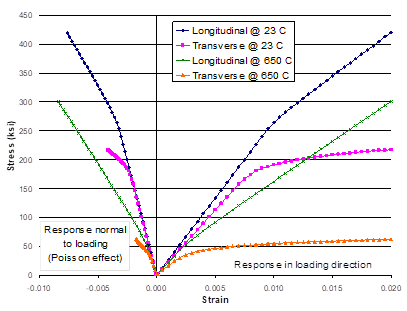

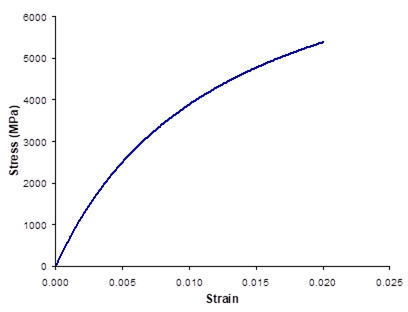

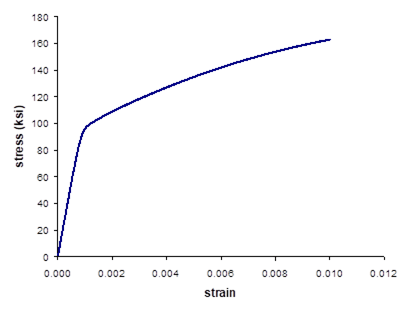

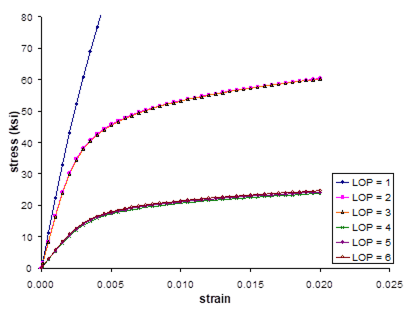

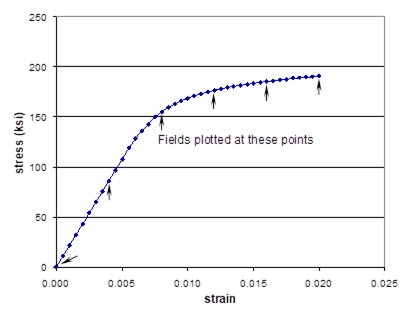

Results are written to both the output file and the x-y plot file in this example. The output file contains all input information regarding the case executed, as well as calculated effective properties and detailed information at each time step in the loading profile (depending on the print level indicated in *PRINT). It is a good idea to check the output file for warnings, which can indicate a problem or unintended result of the input data specified. In the present example, the code has generated two warnings based on the use of TREF and the lack of thermal loading information. The data written to the x-y plot file have been plotted in Figure 1.4. Clearly, the Ti-21S stress-strain response exhibits a significant effect of temperature. Given temperature dependent material properties, MAC/GMC 4.0 captures the temperature dependence in the results, whether for a monolithic material (as in the present case) of for a composite (see Example 1d).

Figure 1.4 Example 1c: plot of the simulated σ11-ε11 stress-strain response of Ti-21S at 23. °C and 650 °C. Note that the 650 °C results were generated by commenting and uncommenting the appropriate lines in the input file under *CONSTITUENTS. Note that the global applied strain rate in this example is 1´10-4/sec.

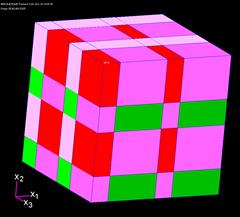

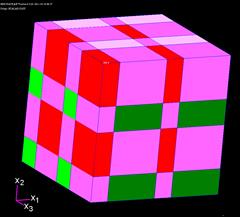

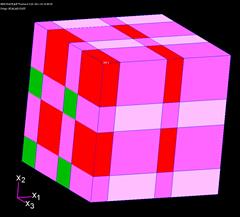

This problem demonstrates several MAC/GMC simulations for a metal matrix composite. The composite is 0.25 fiber volume fraction unidirectional SiC/Ti-21S, and it has been represented with the 2´2 doubly periodic GMC repeating unit cell shown in Figure 1.1. One subcell represents the SiC fiber while the remaining three subcells are associated with the Ti-21S matrix. The material properties for both constituents are taken from the internal material database. Several applied loading cases are considered in this example. By commenting and uncommenting lines under *MECH and *THERM, results are generated for the longitudinal and transverse tensile response of the composite at both 23 °C and 650 °C.

MAC/GMC Input File: example_1d.mac

MAC/GMC 4.0 Example 1d - SiC/Ti-21S mechanical & thermal loading

*CONSTITUENTS

NMATS=2

M=1 CMOD=6 MATID=E

M=2 CMOD=4 MATID=A

*RUC

MOD=2 ARCHID=1 VF=0.25 F=1 M=2

*MECH

LOP=1

# LOP=2

NPT=2 TI=0.,200. MAG=0.,0.02 MODE=1

*THERM

NPT=2 TI=0.,200. TEMP=23.,23.

# NPT=2 TI=0.,200. TEMP=650.,650.

# NPT=2 TI=0.,200. TEMP=23.,650.

*SOLVER

METHOD=1 NPT=2 TI=0.,200. STP=1.

NPL=6

*XYPLOT

FREQ=5

MACRO=4

NAME=example_1d_11 X=1 Y=7

NAME=example_1d_22 X=2 Y=8

NAME=example_1d_11t X=100 Y=1

NAME=example_1d_22t X=100 Y=2

MICRO=0

*END

Annotated Input Data

1) Flags: None

2) Constituent materials (*CONSTITUENTS) [KM_2]:

Number of materials: 2 (NMATS=2)

Materials: SiC fiber (MATID=E)

Ti-21S (MATID=A)

Constitutive models: SiC fiber: linearly elastic (CMOD=6)

Ti-21S matrix: Isotropic GVIPS (CMOD=4)

F Note: In contrast to example 1c, TREF is not included in the constituent data for this example. Thus, the temperature dependent material property data within the MAC/GMC 4.0 internal material database are employed – the code determines the material properties at the current temperature during the simulation. The temperature history is specified under *THERM.

3) Analysis type (*RUC) ® Repeating Unit Cell Analysis [KM_3]:

Analysis model: Doubly periodic GMC (MOD=2)

RUC architecture: square fiber, square pack (ARCHID=1)

Fiber volume fraction: 0.25 (VF=0.25)

Material assignment: SiC fiber (F=1)

Ti-21S matrix (M=2)

In this case, a repeating unit cell (RUC) architecture is selected from the MAC/GMC 4.0 internal library. Further, it is specified which materials from *CONSTITUENTS occupy the subcell associated with the fiber and the subcells associated with the matrix in the chosen RUC (see Figure 1.1).

4) Loading:

a) Mechanical (*MECH) [KM_4]:

Loading option: 1 or 2 (LOP=1 or LOP=2)

Number of points: 2 (NPT=2)

Time points: 0., 200. sec. (TI=0.,200.)

Load magnitudes: 0., 0.02 (MAG=0.,0.02)

Loading mode: strain control (MODE=1)

Included is the line:

# LOP=2

By uncommenting this line and commenting the line above (LOP=1), the loading option can be switched to apply loading in the transverse (x2) direction rather than the longitudinal (x1) direction. As before, in directions other than that of the applied loading, the appropriate stress components are kept at zero.

b) Thermal (*THERM) [KM_4]:

Number of points: 2 (NPT=2)

Time points: 0., 200. sec. (TI=0.,200.)

Temperature points: 23., 23.; 650., 650.; (TEMP=23.,23., TEMP=650.,650., or

23., 650. TEMP=23.,650.)

Much as the applied mechanical loading profile is specified with time-magnitude pairs in *MECH, the applied thermal loading profile is specified with time-temperature pairs in *THERM. Included are the lines:

NPT=2 TI=0.,200. TEMP=23.,23.

# NPT=2 TI=0.,200. TEMP=650.,650.

# NPT=2 TI=0.,200. TEMP=23.,650.

By uncommenting the second line and commenting the first line, the simulation will occur at a temperature of 650 °C rather than 23 °C. For the case of applied pure thermal loading, the first two lines are commented while the third line is uncommented. This causes the code to apply a simulated heat-up from 23 °C to 650 °C. In addition, to eliminate the simulated applied mechanical loading for this case, the entirety of the *MECH section must be commented. Thus, for the pure thermal loading case, the *MECH – *THERM section of the input file should appear as:

#*MECH

# LOP=1

# LOP=2

# NPT=2 TI=0.,200. MAG=0.,0.02 MODE=1

*THERM

# NPT=2 TI=0.,200. TEMP=23.,23.

# NPT=2 TI=0.,200. TEMP=650.,650.

NPT=2 TI=0.,200. TEMP=23.,650.

c) Time integration (*SOLVER) [KM_4]:

Time integration method: Forward Euler (METHOD=1)

Number of time points: 2 (NPT=2)

Time points: 0., 200. sec. (TI=0.,200.)

Time step size: 1. sec. (STP=1.)

5) Damage and Failure: None

6) Output:

a) Output file print level (*PRINT) [KM_6]:

Print level: 6 (NPL=6)

b) x-y plots (*XYPLOT) [KM_6]:

Frequency: 5 (FREQ=5)

Number of macro plots: 4 (MACRO=4)

Macro plot names: example_1d_11 (NAME=example_1d_11)

example_1d_22 (NAME=example_1d_22)

example_1d_11t (NAME=example_1d_11t)

example_1d_22t (NAME=example_1d_22t)

Macro plot x-y quantities: ε11, σ11 (X=1 Y=7)

ε22, σ22 (X=2 Y=8)

temperature, ε11 (X=100 Y=1)

temperature, ε22 (X=100 Y=2)

Number of micro plots: 0 (MICRO=0)

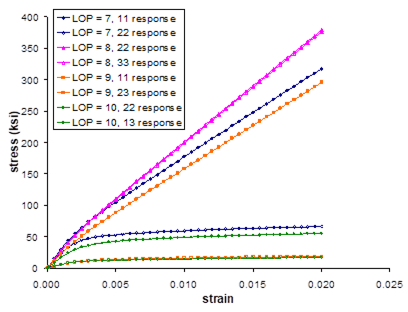

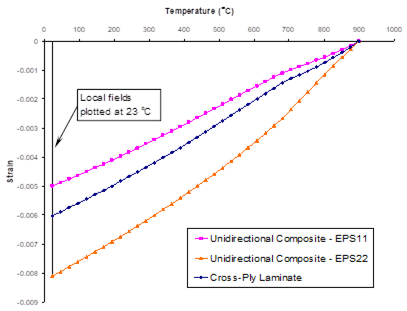

In this example, four macro (repeating unit cell level) x-y plot files are generated, one for the σ11-ε11 stress-strain response, one for the σ22-ε22 stress-strain response, one for the temperature-ε11 response, and one for the temperature-ε22 response. For the case of longitudinal applied loading (LOP=1) and the thermal loading case, the σ22 values written to the x-y plot file will all be zero. Similarly, for the case of transverse applied loading (LOP=2) and the thermal loading case, the σ11 values written to the x-y plot file will all be zero.

7) End of file keyword: (*END)

Results

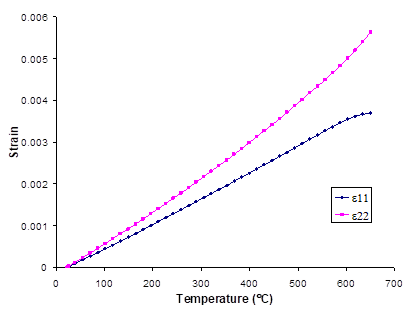

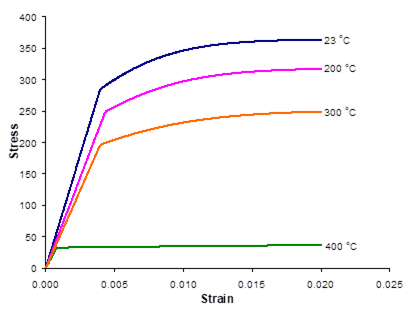

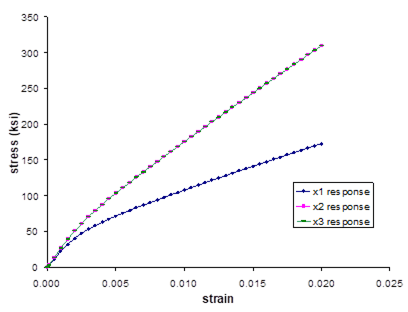

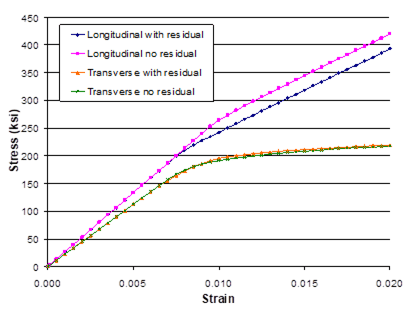

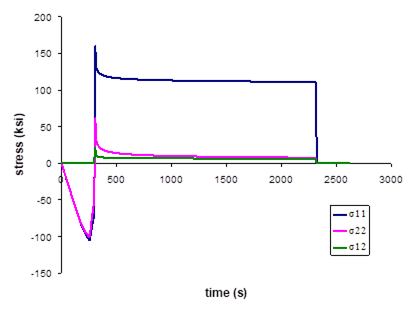

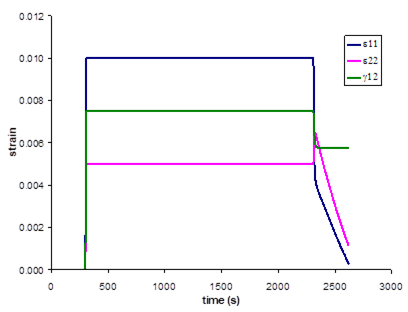

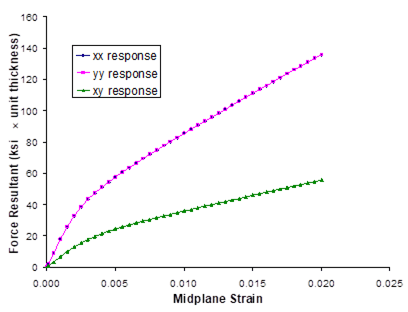

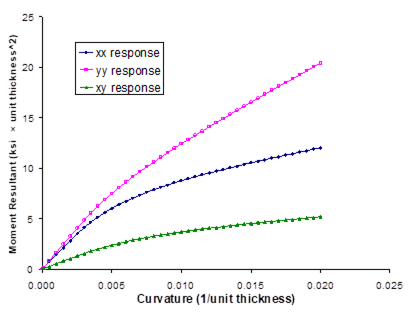

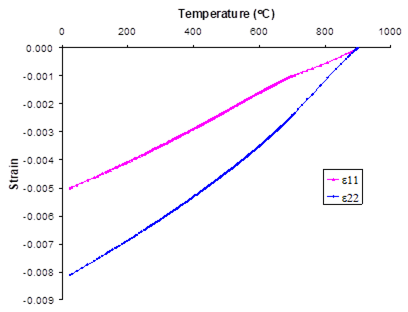

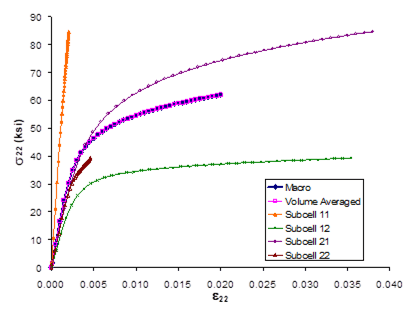

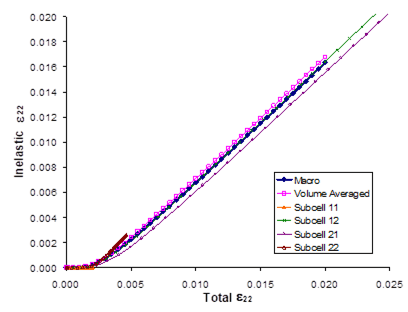

Figure 1.5 presents plots of the composite response to the applied global longitudinal (along fiber the fiber direction) and transverse (perpendicular to the fiber direction) (see Figure 1.1) strain loading at both 23 °C and 650 °C. The right hand side of the plot represents the stress-strain response in the direction of the applied loading, while the left hand side of the plot shows the strain response normal to the loading direction (i.e., the Poisson effect). These results show that the composite is significantly stiffer in the longitudinal fiber direction compared to the direction transverse to the fibers. When the loading is applied transverse to the fiber direction, the resulting Poisson effect strain is small due to the presence of the continuous fibers normal to the loading direction. At elevated temperature, the composite is much softer and exhibits more inelastic deformation than at room temperature. Figure 1.6, which is a plot of the composite’s longitudinal and transverse thermal response to a globally stress free heat up, shows that the composite exhibits greater strain during the thermal loading in the transverse direction compared to the longitudinal direction.

Figure 1.5 Example 1d: plot of the simulated longitudinal (along the fiber direction) and transverse (perpendicular to the fiber direction) stress-strain response of a 25% SiC/Ti-21S composite at 23. °C and 650 °C. The strain response normal to the loading direction (i.e., Poisson effect) is also plotted.

Figure 1.6 Example 1d: plot of the simulated longitudinal and transverse temperature-strain response of a 25% SiC/Ti-21S.

This section presents example problems intended to illustrate MAC/GMC’s capabilities with respect to constituent materials. Constituent materials are the building blocks of the composite materials that the code is designed to analyze. Constituent materials occupy the individual subcells that constitute the repeating unit cell used by the micromechanics models to represent the composite. An important concept related to constituent materials is that of a constitutive model. By definition, associated with each constituent material is a constitutive model. The constitutive model is what determines the reaction of the material to the stresses and strains experienced by the material during a MAC/GMC simulation. Then, based on the reaction of the constituent materials in each subcell, the micromechanics model determines the reaction of the composite as a whole.

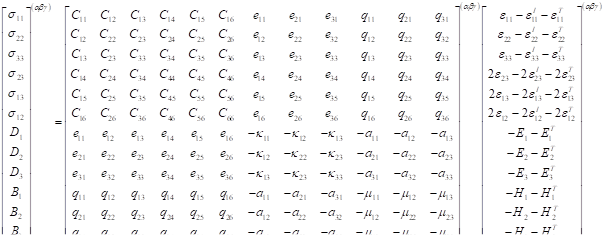

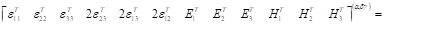

The basic form of the material constitutive equation employed in MAC/GMC 4.0 can be written,

![]()

where ![]() is

the stress vector,

is

the stress vector, ![]() is

the material stiffness matrix,

is

the material stiffness matrix, ![]() is

the strain vector,

is

the strain vector, ![]() is

the inelastic strain vector, and

is

the inelastic strain vector, and ![]() is

the thermal strain vector. The function of the

constitutive model is essentially, given

is

the thermal strain vector. The function of the

constitutive model is essentially, given ![]() (or

(or

![]() ) for the

material at point, to determine

) for the

material at point, to determine ![]() (or

(or

![]() ) at that

point. Thus, the constitutive model for a material must

include information on the stiffness matrix of the material

(

) at that

point. Thus, the constitutive model for a material must

include information on the stiffness matrix of the material

(![]() ), as

well as the inelastic and thermal strains (

), as

well as the inelastic and thermal strains (![]() and

and

![]() ).

Note that MAC/GMC employs this engineering notation wherein the

stress and strain tensors are reduced to vectors. The

ordering of the components within these vectors is: s = (s11, s22, s33, s23, s13, s12) and ε =

(ε 11, ε 22, ε 33,

γ23, γ13, γ12),

where γij are the engineering shear

strain components.

).

Note that MAC/GMC employs this engineering notation wherein the

stress and strain tensors are reduced to vectors. The

ordering of the components within these vectors is: s = (s11, s22, s33, s23, s13, s12) and ε =

(ε 11, ε 22, ε 33,

γ23, γ13, γ12),

where γij are the engineering shear

strain components.

The stiffness matrix and thermal strains within the constitutive equation written above are fairly straight forward. The elastic properties of the material determine the stiffness matrix, while the material coefficient of thermal expansion (CTE), in conjunction with the temperature history, determines the thermal strains. For a linearly elastic material, this is all that is required from the constitutive model. For a material that undergoes inelastic deformation, like the Ti-21S material employed in Example Problems 1c and 1d, the constitutive model must also determine the inelastic strains. This is usually much more complex as inelastic strains typically exhibit history/time/rate dependence, which demands a great deal from the constitutive model, particularly for metals.

MAC/GMC 4.0 includes an internal database of constituent materials, each of which is associated with a particular constitutive model. In Example Problem 1d, two internal database materials, each associated with a different constitutive model, were employed. The Ti-21S matrix material was associated with the isotropic GVIPS viscoplastic constitutive model, while the SiC fiber material was associated with the linearly elastic constitutive model. In Example Problems 1a and 1b, although user-defined material properties were specified for the graphite and epoxy constituent materials, the internal linear elastic constitutive model (CMOD=6) was employed for both materials. Section 2 of this manual presents example problems involving many of the other constituent materials and constitutive models contained within MAC/GMC 4.0. The code also includes the ability for users to employ their own material properties with an internal constitutive model. Further, users may also implement their own material constitutive model through MAC/GMC’s user-defined subroutines. Finally, the users may employ MAC/GMC’s external material database to store and keep track of their material parameters using a simple ASCII interface.

Example 2a: Bodner-Partom Viscoplastic Constitutive Model

This example problem generates the room-temperature tensile stress-strain response of the monolithic constituent materials within the MAC/GMC 4.0 internal material database that are associated with the Bodner-Partom viscoplastic constitutive model. The input file is similar to that employed in Example 1c, with changes associated with the constituent materials. As in Example 1c, this problem examines the response of monolithic inelastic materials and employs an applied strain rate of 10-4/sec.

MAC/GMC Input File: example_2a.mac

MAC/GMC 4.0 Example 2a - Bodner-Partom Viscoplastic Constitutive Model

*CONSTITUENTS

NMATS=7

# -- Al 2024-T4

M=1 CMOD=1 TREF=23. MATID=A

# -- Al 2024-0

M=2 CMOD=1 TREF=23. MATID=B

# -- Al 6061-0 (a)

M=3 CMOD=1 TREF=23. MATID=C

# -- Al 6061-0 (b)

M=4 CMOD=1 TREF=23. MATID=D

# -- Al pure

M=5 CMOD=1 TREF=23. MATID=E

# -- Ti pure

M=6 CMOD=1 TREF=23. MATID=F

# -- Cu

M=7 CMOD=1 TREF=23. MATID=G

*RUC

MOD=1 M=1

# MOD=1 M=2

# MOD=1 M=3

# MOD=1 M=4

# MOD=1 M=5

# MOD=1 M=6

# MOD=1 M=7

*MECH

LOP=1

NPT=2 TI=0.,200. MAG=0.,0.02 MODE=1

*SOLVER

METHOD=1 NPT=2 TI=0.,200. STP=0.025

NPL=6

*XYPLOT

FREQ=10

MACRO=1

NAME=example_2a X=1 Y=7

MICRO=0

*END

Annotated Input Data

1) Flags: None

2) Constituent materials (*CONSTITUENTS) [KM_2]:

Number of materials: 7 (NMATS=7)

Constitutive model: Bodner-Partom (CMOD=1)

Materials: Al 2024-T4, Al 2024-0, (MATID=A-G)

Al 6061-0 (a), Al 6061-0 (b),

Al pure, Ti pure, Cu

Reference Temperature: 23. °C (TREF=23.)

3) Analysis type (*RUC) ® Repeating Unit Cell Analysis [KM_3]:

Analysis model: Monolithic material (MOD=1)

Material assignment: Each constituent successively (M=1-7)

F Note: Each material in *CONSTITUENTS is assigned to the monolithic material successively by commenting and uncommenting the appropriate lines for separate executions of the code.

4) Loading:

a) Mechanical (*MECH) [KM_4]:

Loading option: 1 (LOP=1)

Number of points: 2 (NPT=2)

Time points: 0., 200. sec. (TI=0.,200.)

Load magnitudes: 0., 0.02 (MAG=0.,0.02)

Loading mode: strain control (MODE=1)

b) Thermal (*THERM): None

c) Time integration (*SOLVER) [KM_4]:

Time integration method: Forward Euler (METHOD=1)

Number of time points: 2 (NPT=2)

Time points: 0., 200. sec. (TI=0.,200.)

Time step size: 0.025 sec. (STP=0.025)

F Note: A very small time step size is employed in this example (0.025 sec.) compared to that used in Examples 1c and 1d, which employed the isotropic GVIPS constitutive model (1. sec.). The smaller time step required for convergence of the forward Euler integration scheme is due to the numerically stiff nature of the Bodner-Partom model equations. A smaller time step is directly associated with increased execution time, thus, in many cases it is preferable to employ the alternative time integration method, the predictor-corrector (METHOD=2) when utilizing the Bodner-Partom model as this integration scheme allows for a variable time step. See Example 4h, which employs this predictor-corrector method, for more information.

5) Damage and Failure: None

6) Output:

a) Output file print level (*PRINT) [KM_6]:

Print level: 0 (NPL=0)

F Note: A print level of 0 results in minimal output being written to the output file.

b) x-y plots (*XYPLOT) [KM_6]:

Frequency: 10 (FREQ=10)

Number of macro plots: 1 (MACRO=1)

Macro plot name: example_2a (NAME=example_2a)

Macro plot x-y quantities: ε11, σ11 (X=1 Y=7)

Number of micro plots: 0 (MICRO=0)

7) End of file keyword: (*END)

Results

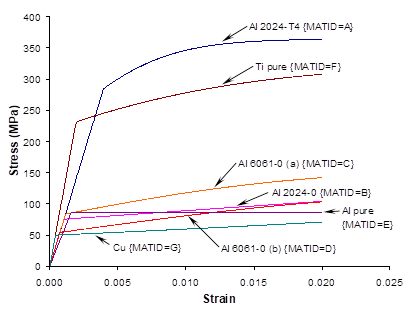

This example problem illustrates how MAC/GMC 4.0 can be used to quickly generate the response of the materials within the internal material database. By altering the materials in *CONSTITUENTS, the user can use the example 2a input file to generate the response of other materials within the code’s internal material database at any temperature desired.

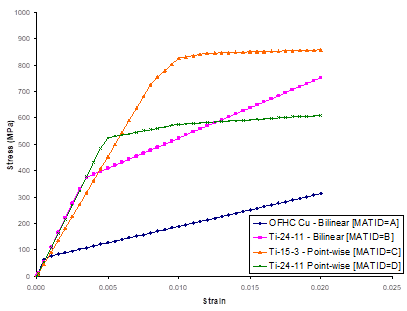

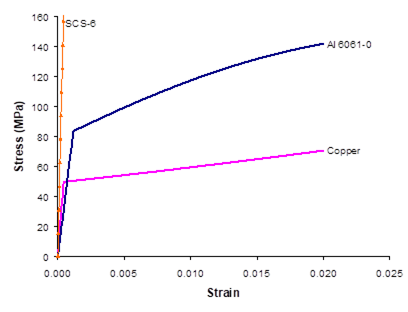

Figure 2.1 Example 2a: plots of the room-temperature tensile stress-strain response of the seven materials within the MAC/GMC 4.0 internal material database that are associated with the Bodner-Partom viscoplastic constitutive model.

Example 2b: Strain-Rate Dependence of Ti-21S

This example problem examines the elevated temperature strain rate (SR) dependence of two different constitutive models for the same material, namely Ti-21S. Ti-21S is associated with both the isotropic GVIPS viscoplastic constitutive model and the modified Bodner-Partom (MBP) viscoplastic constitutive model in the MAC/GMC 4.0 internal material database (see the Keyword Manual Section 2). Both models incorporate strain rate dependence, but, as this example shows, the elevated temperature inelastic behavior of Ti-21S predicted by each of these models is different. The applied strain rate is altered from 10-4/sec. to 10-5/sec. to 10-6/sec. by commenting and uncommenting the appropriate lines under *MECH and *SOLVER.

MAC/GMC Input File: example_2b.mac

MAC/GMC 4.0 Example 2b - Strain Rate Dependence of Ti-21S

*CONSTITUENTS

NMATS=2

# -- Ti-21S Isotropic GVIPS

M=1 CMOD=4 TREF=650. MATID=A

# -- Ti-21S MBP

M=2 CMOD=2 TREF=650. MATID=A

*RUC

MOD=1 M=1

# MOD=1 M=2

*MECH

LOP=1

NPT=2 TI=0.,20. MAG=0.,0.02 MODE=1

# NPT=2 TI=0.,200. MAG=0.,0.02 MODE=1

# NPT=2 TI=0.,2000. MAG=0.,0.02 MODE=1

*SOLVER

METHOD=1 NPT=2 TI=0.,20. STP=0.0025

# METHOD=1 NPT=2 TI=0.,200. STP=0.025

# METHOD=1 NPT=2 TI=0.,2000. STP=0.25

NPL=0

*XYPLOT

FREQ=200

MACRO=1

NAME=example_2b X=1 Y=7

MICRO=0

*END

Annotated Input Data

1) Flags: None

2) Constituent materials (*CONSTITUENTS) [KM_2]:

Number of materials: 2 (NMATS=2)

Constitutive models: Isotropic GVIPS (CMOD=4)

Modified Bodner-Partom (CMOD=2)

Materials: Ti-21S (MATID=A)

Reference Temperature: 650. °C (TREF=650.)

3) Analysis type (*RUC) ® Repeating Unit Cell Analysis [KM_3]:

Analysis model: Monolithic material (MOD=1)

Material assignment: Each constituent successively (M=1,2)

Each of the two materials in *CONSTITUENTS is assigned to the monolithic material successively by commenting and uncommenting the appropriate lines.

4) Loading:

a) Mechanical (*MECH) [KM_4]:

Loading option: 1 (LOP=1)

Number of points: 2 (NPT=2)

Time points: 0., 20. sec. (TI=0.,20.)

0., 200. sec. (TI=0.,200.)

0., 2000. sec. (TI=0.,2000.)

Load magnitude: 0., 0.02 (MAG=0.,0.02)

Loading mode: strain control (MODE=1)

F Note: By altering the time points in the mechanical loading history, the global strain rate is decreased from 10-3/sec. to 10-4/sec. to 10-5/sec.

b) Thermal (*THERM): None

c) Time integration (*SOLVER) [KM_4]:

Time integration method: Forward Euler (METHOD=1)

Number of time points: 2 (NPT=2)

Time points: 0., 20. sec. (TI=0.,20.)

0., 200. sec. (TI=0.,200.)

0., 2000. sec. (TI=0.,2000.)

Time step sizes: 0.0025 sec. (STP=0.0025)

0.025 sec. (STP=0.025)

0.25 sec. (STP=0.25)

As in Example 2a, the very small time step sizes employed in this example are due to the stiff nature of the modified Bodner-Partom equations. A much larger step size can be used for the GVIPS cases presented in this example.

5) Damage and Failure: None

6) Output:

a) Output file print level (*PRINT) [KM_6]:

Print level: 0 (NPL=0)

b) x-y plots (*XYPLOT):

Frequency: 200 (FREQ=200)

Number of macro plots: 1 (MACRO=1)

Macro plot name: example_2b (NAME=example_2b)

Macro plot x-y quantities: ε11, σ11 (X=1 Y=7)

Number of micro plots: 0 (MICRO=0)

7) End of file keyword: (*END)

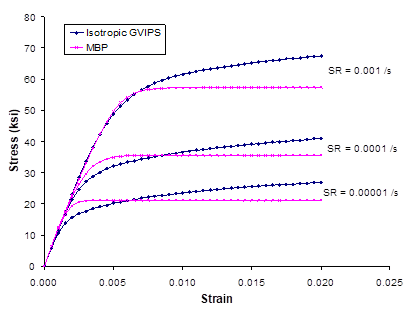

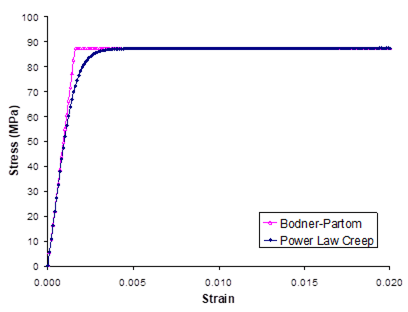

Results

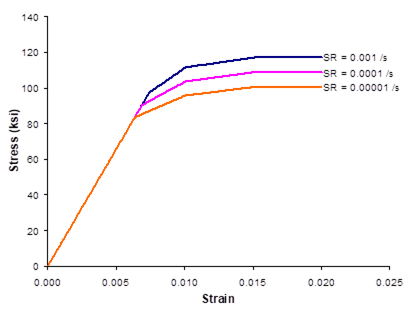

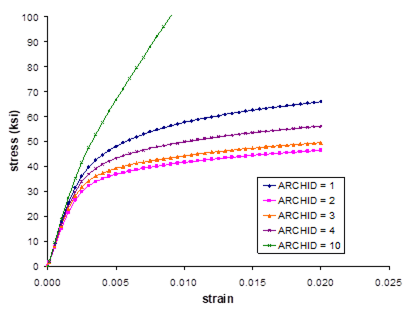

The results for this example problem are shown in Figure 2.2. While the qualitative effect of changing the strain rate is similar for both Ti-21S constitutive models, the predicted stress-strain curves at each strain rate are somewhat different quantitatively. This demonstrates that the different constitutive models within MAC/GMC 4.0 give different results, even for the same material. For an illustration of the impact of these types of constitutive model differences, see Bednarcyk and Arnold (2002).

Figure 2.2 Example 2b: plots of the tensile stress-strain response of Ti-21S at 650 °C as modeled by the isotropic GVIPS and modified Bodner-Partom (MBP) constitutive models as a function of the applied strain rate (SR).

This example problem generates the room-temperature tensile response of the materials associated with the incremental plasticity constitutive model within the MAC/GMC 4.0 internal material database. Incremental plasticity represents a special case for the code in that, due to the presence of a yield surface, global iterations must occur at each increment of the applied loading in order to ensure that the plastically deforming material remains on the yield surface. Further, while the incremental plasticity constitutive model is history-dependent, the modeled inelastic behavior is independent of strain rate. The inelastic behavior of the material is defined by a yield stress and a number of stress-total strain pairs that dictate the path of the stress-strain response after yielding. These stress-total strain pairs can be obtained from experimental stress-strain curves for the material. In the simplest case, if only one post-yield stress-strain pair is specified, bilinear plasticity results. If more than one post-yield stress-strain pair is specified, point-wise plasticity results. The MAC/GMC 4.0 internal material database contains materials with bilinear incremental plasticity responses and two materials with point-wise incremental plasticity responses. This example problem considers the monolithic materials and applies strain at a rate of 10-4/sec.

MAC/GMC Input File: example_2c.mac

MAC/GMC 4.0 Example 2c - Incremental Plasticity

*CONSTITUENTS

NMATS=4

# -- OFHC Copper - Bilinear

M=1 CMOD=21 TREF=23. MATID=A

# -- Ti-24-11 - Bilinear

M=2 CMOD=21 TREF=23. MATID=B

# -- Ti-15-3 - Point-wise

M=3 CMOD=21 TREF=23. MATID=C

# -- Ti-24-11 - Point-wise

M=4 CMOD=21 TREF=23. MATID=D

*RUC

MOD=1 M=1

# MOD=1 M=2

# MOD=1 M=3

# MOD=1 M=4

*MECH

LOP=1

NPT=2 TI=0.,20. MAG=0.,0.02 MODE=1

*SOLVER

METHOD=1 NPT=2 TI=0.,20. STP=0.1 ITMAX=20 ERR=0.0001

NPL=6

*XYPLOT

FREQ=5

MACRO=1

NAME=example_2c X=1 Y=7

MICRO=0

*END

Annotated Input Data

1) Flags: None

2) Constituent materials (*CONSTITUENTS) [KM_2]:

Number of materials: 4 (NMATS=4)

Constitutive models: Incremental plasticity (CMOD=21)

Materials: OFHC Cu – bilinear (MATID=A)

Ti-24-11 – bilinear (MATID=B)

Ti-15-3 – point-wise (MATID=C)

Ti-24-11 – point-wise (MATID=D)

Reference Temperature: 23. °C (TREF=23.)

3) Analysis type (*RUC) ® Repeating Unit Cell Analysis [KM_3]:

Analysis model: Monolithic material (MOD=1)

Material assignment: Each constituent successively (M=1-4)

Each of the materials in *CONSTITUENTS is assigned to the monolithic material successively by commenting and uncommenting the appropriate lines.

4) Loading:

a) Mechanical (*MECH) [KM_4]:

Loading option: 1 (LOP=1)

Number of points: 2 (NPT=2)

Time points: 0., 20. sec. (TI=0.,20.)

Load magnitude: 0., 0.02 (MAG=0.,0.02)

Loading mode: strain control (MODE=1)

b) Thermal (*THERM): None

c) Time integration (*SOLVER) [KM_4]:

Time integration method: Forward Euler (METHOD=1)

Number of time points: 2 (NPT=2)

Time points: 0., 20. sec. (TI=0.,20.)

Time step sizes: 0.1 sec. (STP=0.1)

Max. number of iterations 20 (ITMAX=20)

Max. permitted error fraction 0.0001 (ERR=0.0001)

Due to the necessity of iteration at each time step in the simulation, two additional specifiers are required under *SOLVER when incremental plasticity is employed for a constituent material. These are the maximum number of iterations permitted at a particular time step (ITMAX) and the maximum permitted error fraction for convergence (ERR). The maximum number of iterations places a ceiling on the number of iterations at a particular time step. Once this number of iterations is reached, the code will advance to the next time step regardless of whether or not convergence has occurred (in which case a warning will be written to the output file). Generally, this non-convergent situation should be avoided by using a large value for ITMAX. The maximum permitted error fraction is the fractional change in the local effective plastic strain increment between iterations that can be considered “small enough”. That is, for example, if the largest fractional change in the effective plastic strain increment over all subcells at a particular time step is 0.00009, and ERR has been set to 0.0001, convergence is considered to have been achieved for that time step. The appropriate value for ERR is case dependent, and there is an inverse relationship between the time step size and ERR. If oscillations are present in the results, a lower value of ERR and/or a smaller time step should be employed.

5) Damage and Failure: None

6) Output:

a) Output file print level (*PRINT) [KM_6]:

Print level: 6 (NPL=6)

b) x-y plots (*XYPLOT) [KM_6]:

Frequency: 5 (FREQ=5)

Number of macro plots: 1 (MACRO=1)

Macro plot name: example_2c (NAME=example_2c)

Macro plot x-y quantities: ε11, σ11 (X=1 Y=7)

Number of micro plots: 0 (MICRO=0)

7) End of file keyword: (*END)

Results

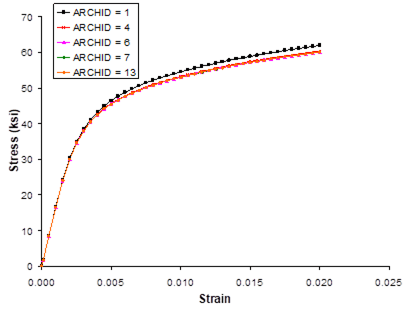

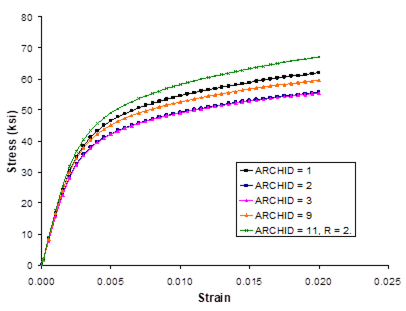

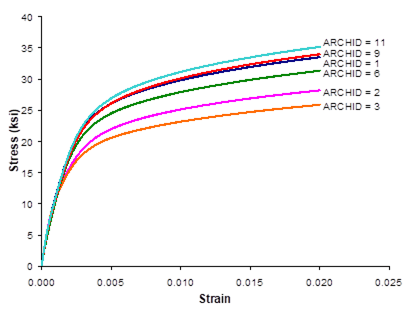

The results for this example problem are plotted in Figure 2.3. The difference between bilinear and point-wise representations of the material stress-strain response is clear.

Figure 2.3 Example 2c: plots of the room-temperature tensile stress-strain response of OFHC Cu, Ti-24-11 (bilinear), Ti-15-3, and Ti-24-11 (point-wise) as modeled by the incremental plasticity constitutive model.

Example 2d: Shape Memory Alloy (SMA)

This example problem generates the tensile response of a NiTi shape memory alloy (SMA), using a specially designed constitutive model, which accounts for phase changes within the material. This model is a new capability within MAC/GMC 4.0. Cyclic strain-controlled mechanical loading is applied to the monolithic SMA at a rate of 0.001/sec.

MAC/GMC Input File: example_2d.mac

MAC/GMC 4.0 Example 2d - Shape Memory Alloy

*CONSTITUENTS

NMATS=1

M=1 CMOD=30 TREF=71.1 MATID=A

# M=1 CMOD=30 TREF=2.2 MATID=A

*RUC

MOD=1 M=1

*MECH

LOP=1

NPT=3 TI=0.,45.,90. MAG=0.,0.045,0. MODE=1,1

*SOLVER

METHOD=1 NPT=3 TI=0.,45.,90. STP=0.25,0.25

NPL=6

*XYPLOT

FREQ=1

MACRO=1

NAME=example_2d X=1 Y=7

MICRO=0

*END

Annotated Input Data

1) Flags: None

2) Constituent materials (*CONSTITUENTS) [KM_2]:

Number of materials: 1 (NMATS=1)

Constitutive models: Graesser – Cozzarelli (CMOD=30)

– Witting SMA model

Materials: NiTi SMA (MATID=A)

Reference Temperatures: 71.1. °C, 2.2 °C (TREF=71.1 or TREF=2.2)

3) Analysis type (*RUC) ® Repeating Unit Cell Analysis [KM_3]:

Analysis model: Monolithic material (MOD=1)

Material assignment: SMA (M=1)

4) Loading:

a) Mechanical (*MECH) [KM_4]:

Loading option: 1 (LOP=1)

Number of points: 3 (NPT=3)

Time points: 0., 45., 90. sec. (TI=0.,45.,90.)

Load magnitude: 0., 0.045, 0. (MAG=0.,0.045,0.)

Loading mode: strain control (MODE=1,1)

In order to illustrate the unique features of the SMA constitutive model, a complete mechanical loading and unloading cycle has been employed.

b) Thermal (*THERM): None

c) Time integration (*SOLVER) [KM_4]:

Time integration method: Forward Euler (METHOD=1)

Number of time points: 3 (NPT=3)

Time points: 0., 45., 90. sec. (TI=0.,45.,90.)

Time step sizes: 0.25, 0.25 sec. (STP=0.25,0.25)

5) Damage and Failure: None

6) Output:

a) Output file print level (*PRINT) [KM_6]:

Print level: 6 (NPL=6)

b) x-y plots (*XYPLOT) [KM_6]:

Frequency: 5 (FREQ=5)

Number of macro plots: 1 (MACRO=1)

Macro plot name: example_2d (NAME=example_2d)

Macro plot x-y quantities: ε11, σ11 (X=1 Y=7)

Number of micro plots: 0 (MICRO=0)

7) End of file keyword: (*END)

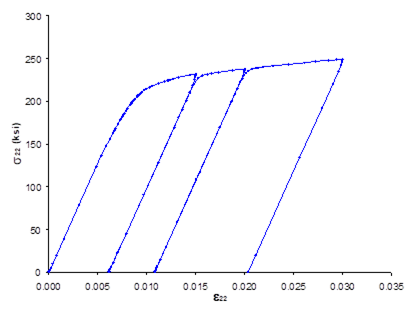

Results

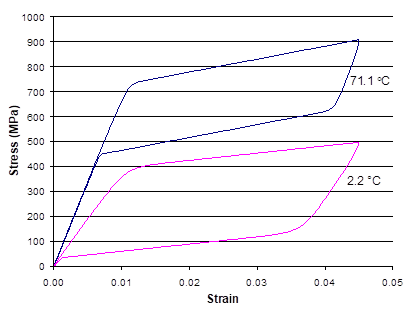

Figure 2.4 shows that, at both temperatures, the implemented constitutive model captures the superelastic behavior of the NiTi SMA. That is, upon mechanical unloading, the SMA returns to its original shape. This “shape memory” behavior is due to stress-induced phase transformations that occur in the NiTi during loading and unloading, as modeled by the Graesser – Cozzarelli – Witting SMA constitutive model. Upon complete mechanical unloading, the stress-strain curves return to the origin, indicating that no permanent or irreversible deformation has occurred.

Figure 2.4 Example 2d: plots of the tensile stress-strain response of the NiTi SMA as simulated using the Graesser – Cozzarelli – Witting constitutive model at 71.1 °C and 2.2 °C.

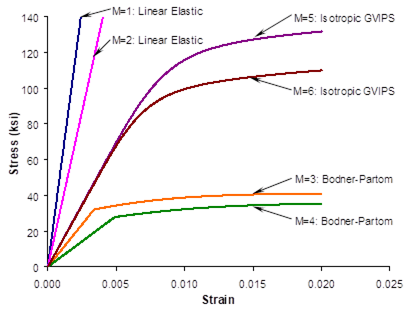

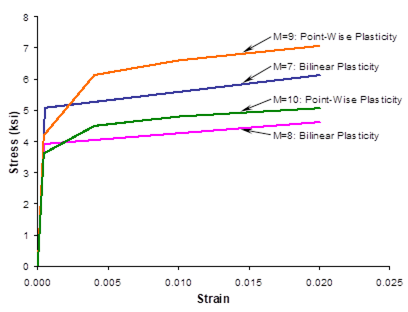

Example 2e: User-Defined Material Properties – Input File

This example problem shows how users can specify their own constituent material properties for internal MAC/GMC 4.0 constitutive models through the code’s input file. Note that Example Problems 1a and 1b touched on this subject. The present example includes ten materials in order to illustrate the input format for the elastic, Bodner-Partom, isotropic GVIPS, and incremental plasticity constitutive models (resulting in a large input file). To switch among the materials in separate code executions, the appropriate material number is specified under *RUC. A strain rate of 10-4/sec. is employed, and results are generated for at a temperature of 500 °C. Another way in which the user can specify constituent material properties is through the use of a user-defined subroutine, which can calculate the material properties as a function of temperature or other quantity during code execution. This type of problem is illustrated in Example 2f. In the present example, the temperature-dependent or temperature-independent material properties are typed directly into the input file. It should be noted that the input file format for user-defined material properties is slightly different for each material constitutive model (as necessitated by the different material parameters needed for each constitutive model). See Section 2 of the MAC/GMC 4.0 Keywords Manual for more information on user-defined material properties.

MAC/GMC Input File: example_2e.mac

MAC/GMC 4.0 Example 2e - User-Defined Material Properties

*CONSTITUENTS

NMATS=10

# -- Elastic; Temp-independent

M=1 CMOD=6 MATID=U MATDB=1 &

EL=58.E3,58.E3,0.20,0.20,24.17E3,6.3E-6,6.3E-6

# -- Elastic; Temp-dependent

M=2 CMOD=6 MATID=U MATDB=1

NTP=4

TEM=18.,200.,400.,600.

EA=45.6E3,43.5E3,40.6E3,29.0E3

ET=45.6E3,43.5E3,40.6E3,29.0E3

NUA=0.41,0.41,0.41,0.41

NUT=0.41,0.41,0.41,0.41

GA=16.154E3,15.429E3,14.400E3,10.286E3

ALPA=4.5E-6,4.8E-6,5.1E-6,5.5E-6

ALPT=4.5E-6,4.8E-6,5.1E-6,5.5E-6

# -- Bodner-Partom; Temp-independent

M=3 CMOD=1 MATID=U MATDB=1 &

EL=9.53E3,9.53E3,0.33,0.33,3.58E3,21.06E-6,21.06E-6 &

VI=1.E4,49.,63.,300.,4.,1.

# -- Bodner-Partom; Temp-dependent

M=4 CMOD=1 MATID=U MATDB=1

NTP=2

TEM=18.,700.

EA=9.53E3,4.12E3

ET=9.53E3,4.12E3

NUA=0.41,0.41

NUT=0.41,0.41

GA=3.58E3,1.46E3

ALPA=21.06E-6,28.92E-6

ALPT=21.06E-6,28.92E-6

V1=1.E4,1.E4

V2=49.,49.

V3=63.,63.

V4=300.,300.

V5=4.,2.5

V6=1.,1.

# -- Isotropic GVIPS; Temp-independent

M=5 CMOD=4 MATID=U MATDB=1 &

EL=14009.,14009.,0.365,0.365,5131.5,5.862E-6,5.862E-6 &

VI=0.000999275,44.960,1.679E-07,2.494561E-05,0.05, &

3.3,1.8,1.35,0.85,3.0183E-7,0.001

# -- Isotropic GVIPS; Temp-dependent

M=6 CMOD=4 MATID=U MATDB=1

NTP=6

TEM=25.,300.,482.,565.,650.,704.

EA=16.5506E+03,15.644E+03,14.009E+03,12.968E+03,11.702E+03,10.793E+03

ET=16.5506E+03,15.644E+03,14.009E+03,12.968E+03,11.702E+03,10.793E+03

NUA=0.365,0.365,0.365,0.365,0.365,0.365

NUT=0.365,0.365,0.365,0.365,0.365,0.365

GA=6062.491,5730.403,5131.502,4750.183,4286.477,3953.480

ALPA=4.2921E-06,5.116E-06,5.862E-06,6.271E-06,6.741E-06,7.07E-06

ALPT=4.2921E-06,5.116E-06,5.862E-06,6.271E-06,6.741E-06,7.07E-06

V1=99.927,20.015,0.000999275,8.499E-08,8.E-8,1.02973E-12

V2=149.964,111.965,44.960,4.786,0.8499,0.10877

V3=0.,0.,1.679E-07,1.685E-07,0.000001,0.00006

V4=9.992748E-06,1.493836E-05,2.494561E-05,7.048586E-05, &

8.498912E-05,9.224075E-05

V5=0.05,0.05,0.05,0.05,0.05,0.05

V6=3.3,3.3,3.3,3.3,3.3,3.3

V7=1.8,1.8,1.8,1.8,1.8,1.8

V8=1.35,1.35,1.35,1.35,1.35,1.35

V9=0.8498912,0.8498912,0.8498912,0.8498912,0.8498912,0.8498912

V10=1.7984E-8,3.6484E-8,3.0183E-7,3.5965E-7,1.5246E-7,1.3429E-7

V11=0.001,0,0,0,0,0

# -- Bilinear plasticity; Temp-independent

M=7 CMOD=21 MATID=U MATDB=1 &

EL=10000.,10000.,0.326,0.326,3770.,12.00E-6,12.00E-6 &

NP=1 VI=5.08,13.1,0.15

# -- Bilinear plasticity; Temp-dependent

M=8 CMOD=21 MATID=U MATDB=1

NTP=3

TEM=21.,400.,800.

EA=10000.,9000.,7300.

ET=10000.,9000.,7300.

NUA=0.326,0.351,0.345

NUT=0.326,0.351,0.345

GA=3771.,3331.,2714.

ALPA=12.00E-6,13.50E-6,22.72E-6

ALPT=12.00E-6,13.50E-6,22.72E-6

NP=1

V1=5.08,4.21,3.05

V2=13.1,10.7,5.10

V3=0.15,0.15,0.15

# -- Point-wise plasticity; Temp-independent

M=9 CMOD=21 MATID=U MATDB=1 &

EL=10000.,10000.,0.326,0.326,3770.,12.00E-6,12.00E-6 &

NP=3 VI=4.20,6.13,6.60,13.1,0.004,0.01,0.15

# -- Point-wise plasticity; Temp-dependent

M=10 CMOD=21 MATID=U MATDB=1

NTP=3

TEM=21.,400.,800.

EA=10000.,9000.,7300.

ET=10000.,9000.,7300.

NUA=0.326,0.351,0.345

NUT=0.326,0.351,0.345

GA=3771.,3331.,2714.

ALPA=12.00E-6,13.50E-6,22.72E-6

ALPT=12.00E-6,13.50E-6,22.72E-6

NP=3

V1=4.20,3.81,3.05

V2=6.13,4.77,3.69

V3=6.60,5.10,3.90

V4=13.1,9.70,5.10

V5=0.004,0.004,0.004

V6=0.01,0.01,0.01

V7=0.15,0.15,0.15

*RUC

# -- Alter value of M=* to change simulated material

MOD=1 M=1

*MECH

LOP=1

NPT=2 TI=0.,200. MAG=0.,0.02 MODE=1

*THERM

NPT=2 TI=0.,200. TEMP=500.,500.

*SOLVER

METHOD=1 NPT=2 TI=0.,200. STP=0.1 ITMAX=20 ERR=1.E-6

NPL=6

*XYPLOT

FREQ=1

MACRO=1

NAME=example_2e X=1 Y=7

MICRO=0

*END

Annotated Input Data

1) Flags: None

2) Constituent materials (*CONSTITUENTS) [KM_2]:

Number of materials: 10 (NMATS=10)

Materials: User-Defined (MATID=U)

Material property source: Read from input file (MATDB=1)

Constitutive models:

Linear Elastic (CMOD=6)

# -- Elastic; Temp-independent

M=1 CMOD=6 MATID=U MATDB=1 &

EL=58.E3,58.E3,0.20,0.20,24.17E3,6.3E-6,6.3E-6

# -- Elastic; Temp-dependent

M=2 CMOD=6 MATID=U MATDB=1

NTP=4

TEM=18.,200.,400.,600.

EA=45.6E3,43.5E3,40.6E3,29.0E3

ET=45.6E3,43.5E3,40.6E3,29.0E3

NUA=0.41,0.41,0.41,0.41

NUT=0.41,0.41,0.41,0.41

GA=16.154E3,15.429E3,14.400E3,10.286E3

ALPA=4.5E-6,4.8E-6,5.1E-6,5.5E-6

ALPT=4.5E-6,4.8E-6,5.1E-6,5.5E-6

The simplest constitutive model for

which to input user-defined material properties is the

linearly elastic model (CMOD=6).

Since the material deformation is treated as linearly elastic, all

that is needed is the thermo-elastic material properties. The

standard order for the material properties is: ![]() .

As shown above, for temperature-independent material

properties, these properties are simply listed as

EL=…,

on the same line in the input file. For

temperature-dependent material properties, the number of input

temperatures (NTP=4)

is placed on a separate line, followed by a separate line

specifying the input temperatures

(TEM=…).

Then, each of the seven material properties is placed on its own

separate line, with the values at each of the input temperatures

listed.

.

As shown above, for temperature-independent material

properties, these properties are simply listed as

EL=…,

on the same line in the input file. For

temperature-dependent material properties, the number of input

temperatures (NTP=4)

is placed on a separate line, followed by a separate line

specifying the input temperatures

(TEM=…).

Then, each of the seven material properties is placed on its own

separate line, with the values at each of the input temperatures

listed.

Bodner-Partom (CMOD=1)

# -- Bodner-Partom; Temp-independent

M=3 CMOD=1 MATID=U MATDB=1 &

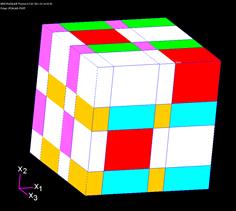

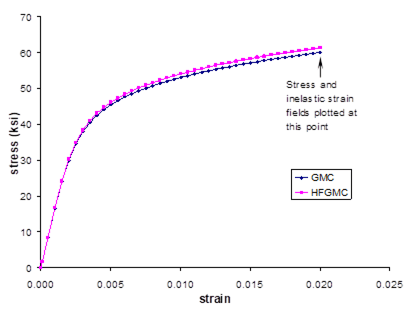

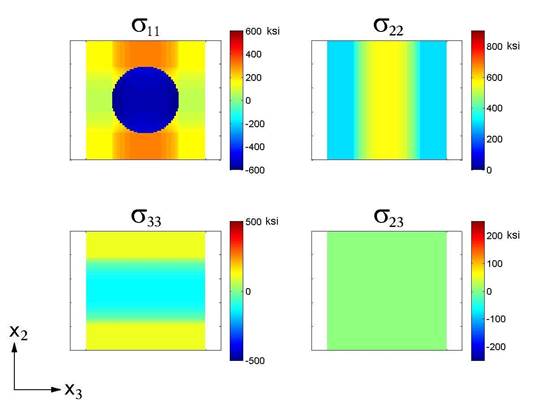

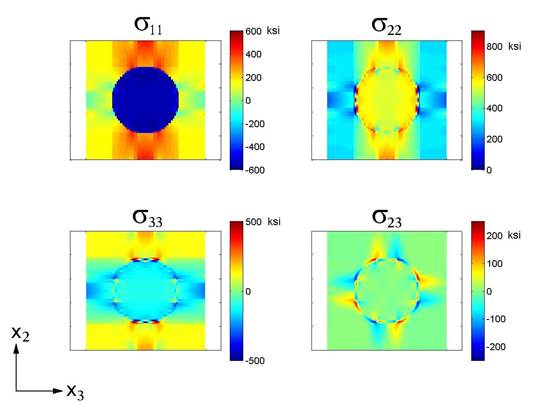

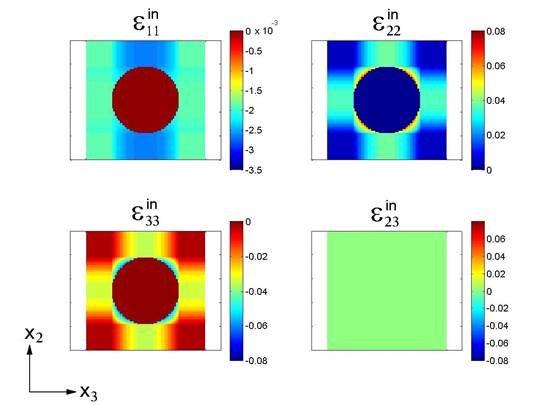

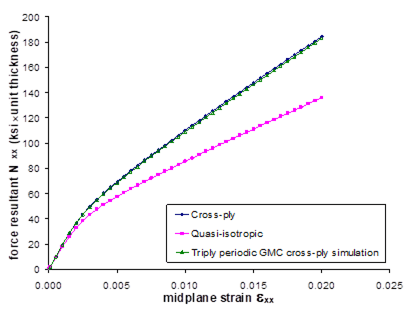

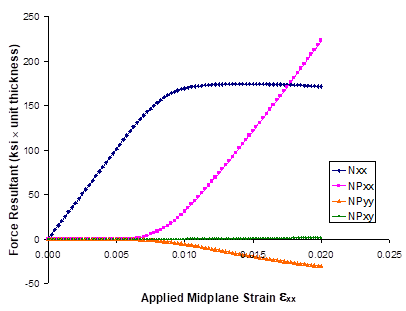

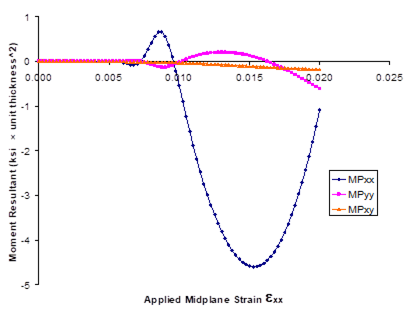

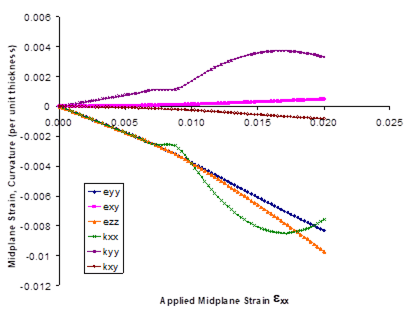

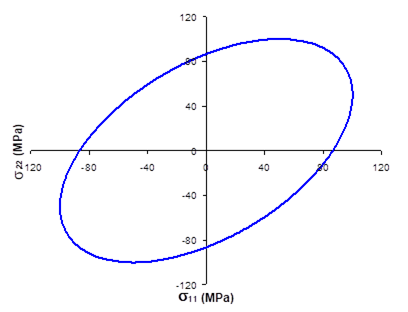

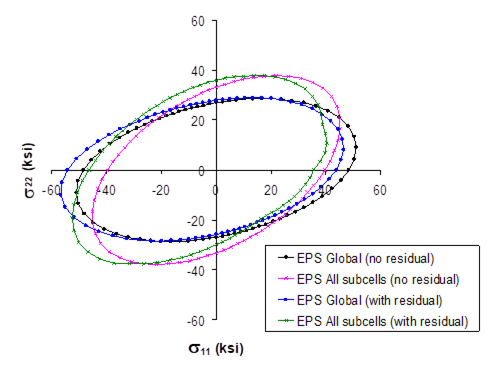

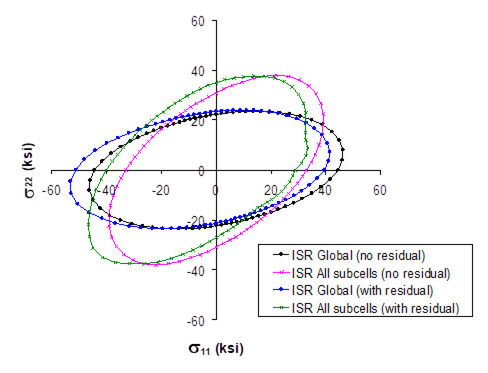

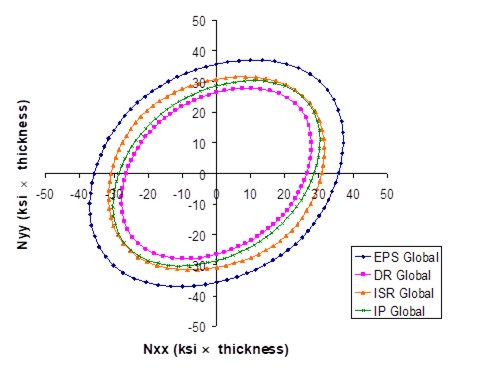

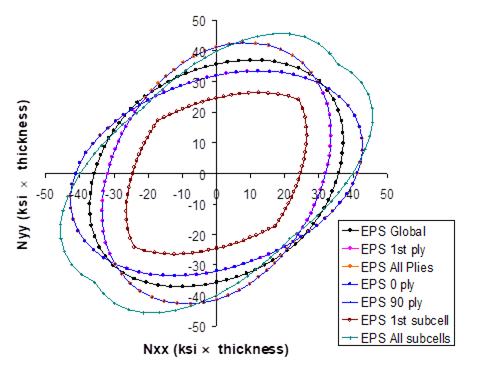

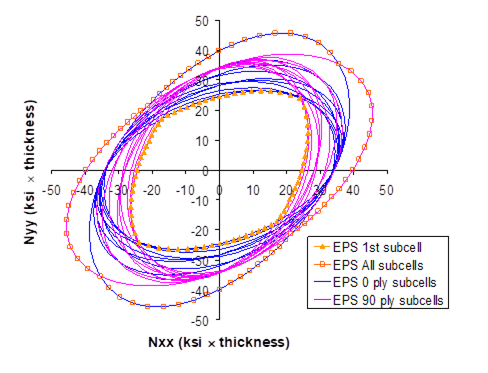

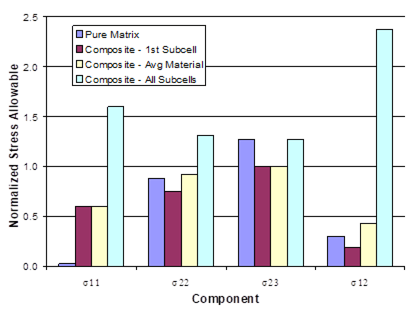

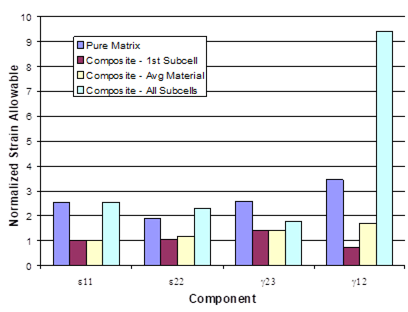

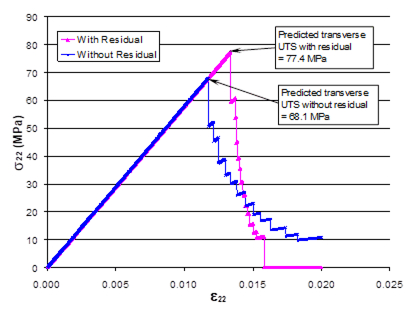

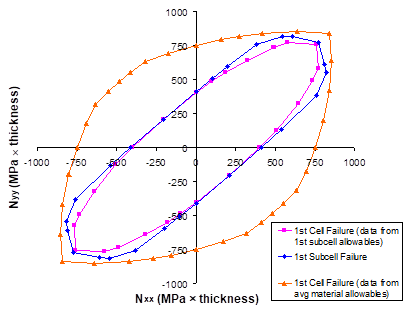

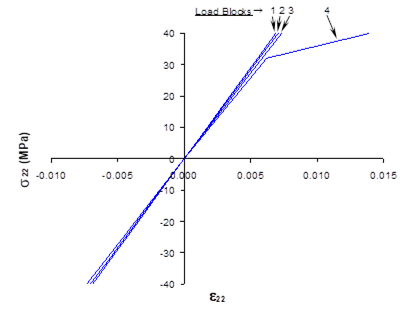

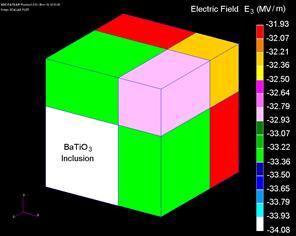

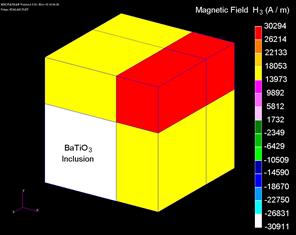

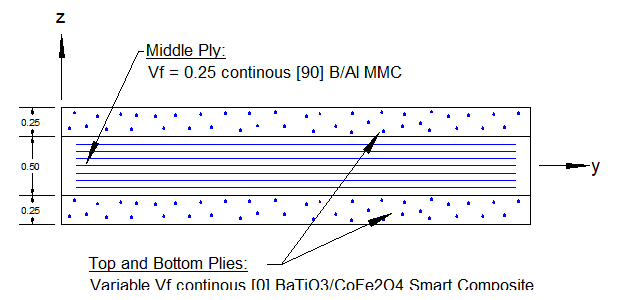

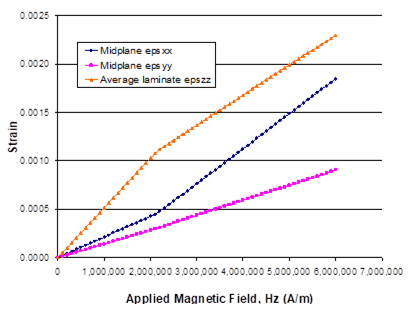

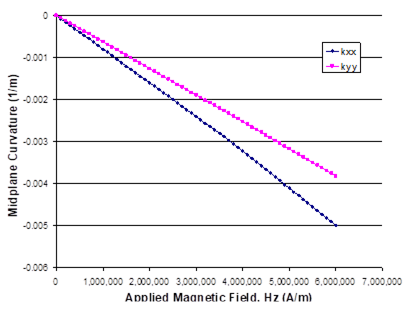

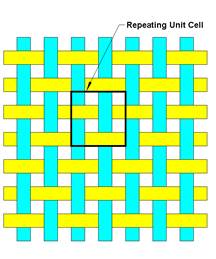

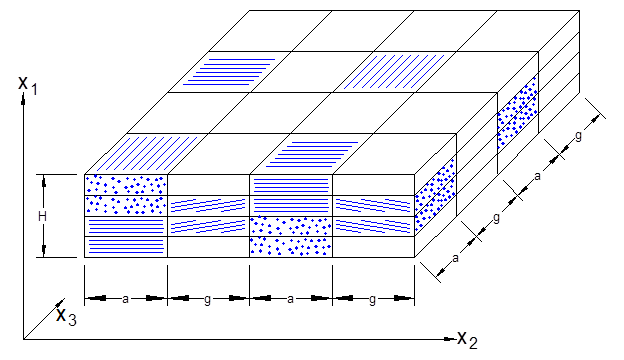

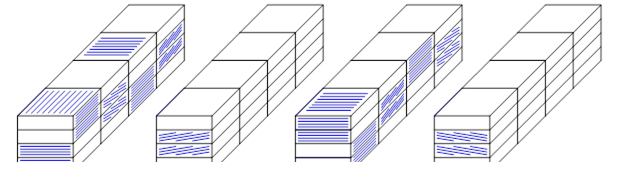

EL=9.53E3,9.53E3,0.33,0.33,3.58E3,21.06E-6,21.06E-6 &