MAC/GMC 4.0 Example Manual

MAC/GMC 4.0 User’s Manual

Volume 2:

Keywords Manual

Brett A. Bednarcyk

Steven M. Arnold

Table of Contents............................................................................................................................... 1

Introduction....................................................................................................................................... 2

Current Capabilities and What’s New in MAC/GMC 4.0................................................................... 3

Format of this Manual.................................................................................................................. 6

Getting Started................................................................................................................................... 7

Distributed Files.......................................................................................................................... 7

Executing MAC/GMC 4.0 Problems................................................................................................ 7

Using User-Defined Subroutines with MAC/GMC 4.0...................................................................... 9

Format of the MAC/GMC 4.0 Input File........................................................................................ 10

Section 1 : Flag-Type Keywords......................................................................................................... 12

*CHECK: Check input file for errors................................................................................................ 13

*CONDUCTIVITY: Effective thermal conductivities.......................................................................... 14

*ELECTROMAG: Electromagnetic analysis....................................................................................... 16

Section 2 : Material Keywords............................................................................................................ 18

*MDBPATH: External material database file & location..................................................................... 19

*CONSTITUENTS: Constituent (subcell) materials........................................................................... 21

Section 3 : Analysis Type and Architecture Keywords.......................................................................... 45

*RUC: Repeating unit cell analysis and architecture........................................................................ 48

*LAMINATE: Laminate analysis and architecture............................................................................ 60

Section 4 : Loading Keywords............................................................................................................ 64

*MECH: Applied mechanical loading............................................................................................... 66

*THERM: Applied thermal loading................................................................................................... 70

*SOLVER: Time integration........................................................................................................... 72

*SURF: Yield Surface Analysis....................................................................................................... 76

Section 5 : Damage and Failure Keywords.......................................................................................... 79

*ALLOWABLES: Estimated elastic allowables.................................................................................. 80

*FAILURE_SUBCELL: Subcell static failure.................................................................................... 83

*FAILURE_CELL: Repeating unit cell static failure......................................................................... 86

*DAMAGE: Fatigue damage analysis............................................................................................... 88

*DEBOND: Fiber-matrix interfacial debonding.................................................................................. 94

*CURTIN: Curtin effective fiber breakage model............................................................................. 98

Section 6 : Results and Data Output Keywords................................................................................. 100

*PRINT: Overall print output level for output file.......................................................................... 101

*XYPLOT: X-Y plot output........................................................................................................... 102

*PATRAN: PATRAN post-processing data output........................................................................... 108

*MATLAB: MATLAB post-processing data output........................................................................... 110

Section 7 : End of File Keyword....................................................................................................... 112

*END: End of input file................................................................................................................ 113

References..................................................................................................................................... 114

Appendix........................................................................................................................................ 115

User-Defined Constituent Material Constitutive Model File (usrmat.F90)...................................... 116

User-Defined Stiffness Matrix Determination File (usrformde.F90).............................................. 121

User-Defined Material Property Determination File (usrfun.F90)................................................. 123

Sample external material database file.......................................................................................... 129

MATLAB source files for generation of fringe plots (stress.m, strain.m, epsp.m).................. 130

Index............................................................................................................................................. 147

This document is the second volume in the three volume set of User’s Manuals for the Micromechanics Analysis Code with Generalized Method of Cells Version 4.0 (MAC/GMC 4.0). Volume 1 is the Theory Manual, this document is the Keywords Manual, and Volume 3 is the Example Problem Manual.

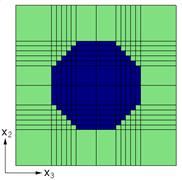

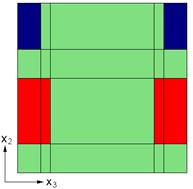

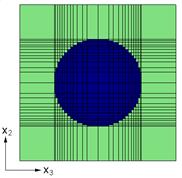

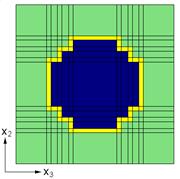

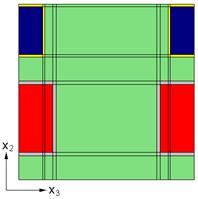

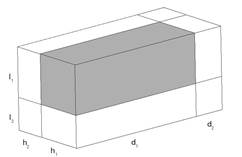

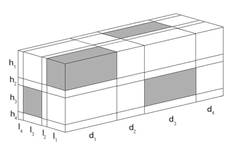

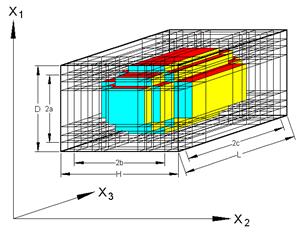

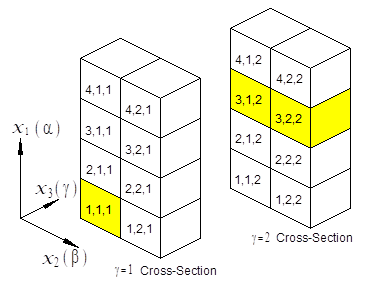

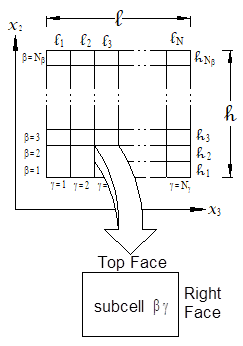

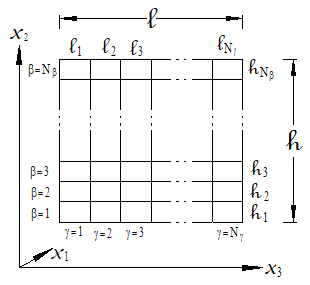

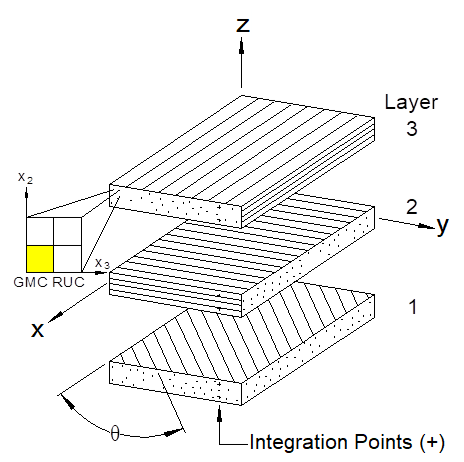

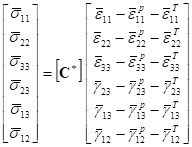

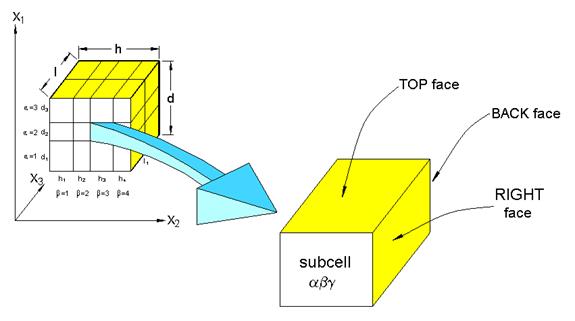

MAC/GMC 4.0 is a computer code developed at NASA Glenn Research Center that analyzes the thermo-inelastic behavior of composite materials and laminates. The code is based on the micromechanics theory known as the generalized method of cells (GMC). GMC models the response of composite materials using a doubly or triply periodic repeating unit cell (RUC), which is composed of a number of subcells (see Figure 3.1 and Figure 3.2). By placing distinct constituent materials within the subcells, a heterogeneous (composite) material can be modeled, provided an RUC can be identified in the material’s micro scale architecture. The main advantages of GMC over other micromechanics theories and approaches are: 1) its fully multi-axial formulation, 2) the availability of local (constituent level) stress and strain fields, and 3) its computational efficiency. The availability of the local fields makes the method attractive in situations where more detailed composite analysis, beyond simple determination of effective thermo-elastic properties, is necessary. In such situations, when matrix inelasticity, constituent damage or failure, or fiber-matrix debonding is important, the availability of the local fields is critical in order to account for these effects appropriately. It is the purpose of the MAC/GMC 4.0 code to provide a convenient and user-friendly “package” for the GMC theories, in addition to providing significant added value through a library of inelastic constitutive models, repeating unit cells, thermo-mechanical and yield surface loading options, failure and damage analysis capabilities, and results generation options.

The original method of cells (which allowed only four subcells) was developed by Aboudi (1989, 1991), the doubly periodic version of GMC by Paley and Aboudi (1992), and the triply periodic version of GMC by Aboudi (1995). The actual GMC theories implemented within MAC/GMC 4.0 were reformulated for maximum computational efficiency by Pindera and Bednarcyk (1999) and Bednarcyk and Pindera (2000). A recent advancement in the GMC technology has significantly improved the local accuracy of the doubly periodic version of the model. This new micromechanics theory, called the high-fidelity generalized method of cells (HFGMC), developed by Aboudi et al. (2001, 2002), has also been implemented with MAC/GMC 4.0.

As mentioned, MAC/GMC 4.0 is also capable of analyzing composite laminates. The composite laminate analysis capabilities also rely on the GMC composite material model. The doubly and triply periodic versions of GMC function within the context of classical lamination theory (Jones, 1975; Herakovich, 1998) to model the ply level composite material. Thus, the code can analyze the thermo-inelastic behavior of arbitrary laminate configurations.

Finally, a new thermo-electro-magnetic version of GMC that is capable of modeling so-called “smart” composites has been implemented within MAC/GMC 4.0. The implementation also enables the analysis of smart composite laminates. This specific form of the thermo-electro-magnetic GMC was developed by Bednarcyk (2002) based on the work of Aboudi (2000).

Current Capabilities and What’s New in MAC/GMC 4.0

The current capabilities of MAC/GMC are listed below, with new or improved features in this version highlighted in bold blue type. The superscripts refer to the enumerated details regarding these new features given after the list.

Current Capabilities

· Usability

![]() Intuitive

ASCII user

interface1

Intuitive

ASCII user

interface1

![]() A

graphical user interface (GUI) for MAC/GMC

4.0 will be available in March 2002

A

graphical user interface (GUI) for MAC/GMC

4.0 will be available in March 2002

![]() Computer

resource management2

Computer

resource management2

- Dynamic memory allocation

- Static problem size limitations removed

- Improved efficiency of solution for laminate analysis and large problems

![]() 43 new

example problems are described in the MAC/GMC 4.0

Example Problem Manual and are distributed with the

code

43 new

example problems are described in the MAC/GMC 4.0

Example Problem Manual and are distributed with the

code

· Material Constitutive Models5

![]() Elastic: isotropic, transversely

isotropic,

completely

anisotropic

Elastic: isotropic, transversely

isotropic,

completely

anisotropic

![]() Inelastic:

Bodner-Partom,

Robinson, isotropic

GVIPS,

transversely isotropic GVIPS, multimechanism GVIPS,

SMA, incremental plasticity, Freed-Walker

Inelastic:

Bodner-Partom,

Robinson, isotropic

GVIPS,

transversely isotropic GVIPS, multimechanism GVIPS,

SMA, incremental plasticity, Freed-Walker

![]() User-defined:

user-defined constitutive

model subroutine

(usrmat.F90)

User-defined:

user-defined constitutive

model subroutine

(usrmat.F90)

· Library of Material Properties

![]() Expanded

internal material property library

Expanded

internal material property library

![]() Temperature-dependent

or temperature-independent properties specified in

input file

Temperature-dependent

or temperature-independent properties specified in

input file

![]() User-defined

subroutine (usrfun.F90)

for calculating material properties as a function of

temperature or other variable

User-defined

subroutine (usrfun.F90)

for calculating material properties as a function of

temperature or other variable

![]() External

material property database file6

External

material property database file6

· Micromechanics Analysis Models

![]() Doubly periodic

generalized method of cells

Doubly periodic

generalized method of cells

![]() Triply periodic

generalized method of cells

Triply periodic

generalized method of cells

![]() Doubly Periodic

High-Fidelity Generalized Method of

Cells (HFGMC)4

Doubly Periodic

High-Fidelity Generalized Method of

Cells (HFGMC)4

· Library of Doubly and Triply Periodic Repeating Unit Cell Architectures

· Laminate Analysis Model (Classical Lamination Theory)

![]() Monolithic

layers

Monolithic

layers

![]() Doubly periodic

composite layers

Doubly periodic

composite layers

![]() Triply

periodic composite layers7

Triply

periodic composite layers7

![]() Improved

interoperability (doubly and triply periodic layers in the same

laminate)7

Improved

interoperability (doubly and triply periodic layers in the same

laminate)7

· Smart Material Analysis Capabilities

![]() Shape

memory alloy (SMA)

model5

Shape

memory alloy (SMA)

model5

![]() Fully

coupled thermo-electro-magneto-elasto-plastic

analysis3

Fully

coupled thermo-electro-magneto-elasto-plastic

analysis3

- Constituent material (arbitrary poling direction)

- Composite

- Laminate

· Library of Applied Loading History Options

![]() Thermal, uniaxial,

biaxial, general (arbitrary) loading, thermo-mechanical

Thermal, uniaxial,

biaxial, general (arbitrary) loading, thermo-mechanical

![]() Curvature and moment

loading for

laminate

Curvature and moment

loading for

laminate

![]() Electromagnetic

loading

Electromagnetic

loading

· Time Integration Options

![]() Forward

Euler

Forward

Euler

![]() Self-Adaptive

Predictor-Corrector

Self-Adaptive

Predictor-Corrector

· Yield Surface Analysis8

![]() GMC, HFGMC, laminate

GMC, HFGMC, laminate

![]() Global

(composite/laminate level),

local (subcell level),

ply level in

laminate

Global

(composite/laminate level),

local (subcell level),

ply level in

laminate

· Failure, Damage, and Lifing Capabilities

![]() Elastic

Allowables Estimation9

Elastic

Allowables Estimation9

![]() Static

Failure Analysis9

Static

Failure Analysis9

- Doubly periodic GMC, triply periodic GMC, laminate

- Subcell level, repeating unit cell level

- Maximum stress, maximum strain, and Tsai-Hill criteria

![]() Weak

Interface Modeling

Weak

Interface Modeling

- Distinct interfacial phase layer

- Interfacial displacement discontinuity modeling (GMC and HFGMC)

![]() Fiber

Breakage Modeling11

Fiber

Breakage Modeling11

- Using internal fiber interface

- Curtin effective fiber breakage model

![]() Fatigue

Damage Analysis10

Fatigue

Damage Analysis10

- Doubly periodic GMC, triply periodic GMC, laminate

- Stiffness reduction, strength reduction

- Improved interoperability – Can be combined with static failure, debonding, and fiber breakage

· Output and Data Visualization12

![]() Unlimited

number of

macro, micro, and laminate x-y plot files

Unlimited

number of

macro, micro, and laminate x-y plot files

![]() MSC/PATRAN output for

use with the MACPOST software

add-on ® fringe

plots

MSC/PATRAN output for

use with the MACPOST software

add-on ® fringe

plots

![]() MATLAB output for

use with distributed MATLAB source files

®

fringe

plots

MATLAB output for

use with distributed MATLAB source files

®

fringe

plots

Details on New Features

1) The format of the MAC/GMC 4.0 input file has been completely overhauled. Unneeded keywords have been eliminated, more logical keyword and specifier names have been utilized, and the placement of specific data has been better organized. The result is a considerably more streamlined and easy to use input file format.

2) The memory allocation of MAC/GMC 4.0 is dynamic. There is no longer a static limit on the size of the problem (i.e., number of subcells and laminate plies) that can be analyzed, the number of constituent materials that can be employed, or the number of x-y plot result files that can be generated. The result is a more robust code that only uses the system resources it needs to execute a given problem.

3) MAC/GMC 4.0 can analyze smart composites and laminates. A major advancement in the generalized method of cells micromechanics models and lamination theory has been implemented within MAC/GMC 4.0: the ability to model fully coupled thermo-electro-magneto-visco-elasto-plastic composite materials and laminates. These so-called “smart” materials and composites react electromagnetically to thermo-mechanical loading and react mechanically to electromagnetic loading. These materials are currently finding a growing number of applications in sensors and actuators and have the potential to enable the next generation of multi-functional structures that can automatically sense and react to various stimuli. See problems 7b and 7c in the MAC/GMC 4.0 Example Manual.

4) A new high-fidelity doubly periodic micromechanics model has been implemented within MAC/GMC 4.0. This new micromechanics model, the high-fidelity generalized method of cells (HFGMC) provides much more accurate local stress and strain field predictions than does the standard method of cells. MAC/GMC 4.0 can therefore perform composite analyses with a variable level of fidelity, maximizing either accuracy or efficiency when appropriate. See problem 3f in the MAC/GMC 4.0 Example Manual.

5) Several new internal material constitutive models have been implemented within MAC/GMC 4.0. These include: a shape memory alloy constitutive model, the classical incremental plasticity model, a new multimechanism visco-elastic-plastic GVIPS model, the Freed-Walker viscoplasticity model, a Robinson isotropic viscoplasticity model for NARloy Z, and a completely anisotropic elastic model. The classical incremental plasticity model is formulated to allow the user to simply input stress-total strain point pairs from a material’s inelastic stress-strain curve. See problems 2c, 2d, 7a, and 7e in the MAC/GMC 4.0 Example Manual.

6) MAC/GMC 4.0 enables the use of an external material database file. User’s can store their own material properties in this external database file, from which the code reads and stores only the material properties specified for use in a specific problem. See problem 2h in the MAC/GMC 4.0 Example Manual.

7) The laminate analysis capabilities have been significantly expanded and computationally enhanced. Discontinuous fiber and particulate reinforced laminate layers can now be analyzed thanks to the ability of triply periodic GMC to represent any particular layer within a laminate. Further, all laminate data is now kept in core memory during execution (previous versions of MAC/GMC performed read/write cycles to disk). This has significantly increased the computational efficiency of MAC/GMC 4.0 laminate analyses. See problem 3i in the MAC/GMC 4.0 Example Manual.

8) The yield surface analysis capabilities of MAC/GMC 4.0 are significantly expanded. Various subcell and repeating unit cell level yield surfaces can be automatically generated for composites using standard or high-fidelity GMC. Further, yield surfaces can now be automatically generated for laminates on the laminate, ply, and micro (subcells within a ply) levels. See problems 4f and 4g the MAC/GMC 4.0 Example Manual.

9) The static failure analysis capabilities of MAC/GMC 4.0 have been significantly enhanced. A simple and quick estimation of composite allowable stress and strain quantities can be performed based on the constituent allowables. Further, true subcell and repeating unit cell level static failure analysis (i.e., checking for failure at various scales during application of simulated thermo-mechanical loading) can be performed using several failure criteria. These failure analyses are available for composites as well as laminates. See problems 5a, 5b, and 5c in the MAC/GMC 4.0 Example Manual.

10) The fatigue damage analysis capabilities of MAC/GMC 4.0 have been significantly enhanced. A new strength reduction fatigue model has been implemented, and the applicability of the stiffness reduction fatigue model has been expanded to include triply periodic repeating unit cells and laminates. Further, both fatigue damage models now work in concert with the MAC/GMC 4.0 static failure and interfacial debonding capabilities to enable mechanistically realistic life predictions for composites and laminates. See problem 5d in the MAC/GMC 4.0 Example Manual.

11) The local fiber failure analysis capabilities of MAC/GMC 4.0 have been improved via inclusion of the Curtin effective fiber breakage model. Based on fiber strength statistical data, the Curtin model is a widely used tool for predicting composite stiffness degradation and failure due to longitudinal fiber fracture. The Curtin model can be used to model fibers within continuous fiber composites and continuous fiber composite layers within laminates. See problem 5f in the MAC/GMC 4.0 Example Manual.

12) The post-processing of MAC/GMC 4.0 results has been significantly improved. The code now automatically generates output for use with the popular MATLAB software package. MATLAB source files are distributed with MAC/GMC 4.0 that generate fringe plots of the stress, strain, and inelastic strain fields predicted by the code. See problem 6c in the MAC/GMC 4.0 Example Manual.

13) MAC/GMC 4.0 has been extensively tested and debugged.

F Note: Attempts have been made to enable a high level of interoperability within MAC/GMC 4.0. However, currently not all of the code’s features can work in concert. For example, the composite layers within a laminate cannot currently be modeled using the new HFGMC micromechanics model. Look for additional improvements in interoperability in future versions of MAC/GMC.

Format of this Manual

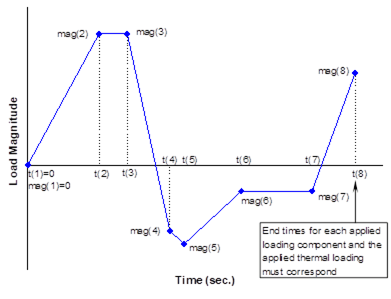

This Keywords Manual first presents a “Getting Started” section that details the installation of the MAC/GMC 4.0 software and how the code can be executed. The bulk of this manual presents detailed information on each of the keywords that may appear in the MAC/GMC 4.0 input file. Each keyword is presented with its purpose, and then the usage of and all specifiers associated with the keyword are described. Optional and special case specifiers are shown in blue type. A “Notes” section for each keyword is referenced via superscripts in the list of specifiers and their descriptions. For example, the specifier t(i) is descibed as,

|

Name |

Definition |

|

t(i) 3 |

Time points in time vs. load magnitude profile |

Here, the superscript “3” would refer to note number 3 in the “Notes” section, which would follow the above description.

One or more examples of the usage of each keyword are given along with any additional information needed to use the keyword. Any example problems (appearing in the Example Problem Manual) associated with the particular keyword are listed, with example problems that are most relevant to the keyword typed in bold. Suggested sources of additional information are also provided when appropriate. In some cases, keyword information is broken into subsections in order to facilitate the presentation of the needed information. Note that the abbreviation N/A is employed throughout this manual to indicate that a particular option is not applicable or unavailable. Finally, – AND – and – OR – are used as logical operators.

Distributed Files

The MAC/GMC 4.0 distribution cd includes the following in its root directory:

|

4 mac4.exe |

MAC/GMC 4.0 executable file

|

|

0 library |

File folder containing the MAC/GMC 4.0 library file and user-defined subroutines |

|

0 examples |

File folder containing the MAC/GMC 4.0 Example Problem input files

|

|

0 manuals |

File folder containing the MAC/GMC 4.0 Theory Manual, Keywords Manual, and Example Problem Manual in PDF format |

|

0 documents |

File folder containing many of the technical references cited in the MAC/GMC 4.0 manuals in PDF format |

|

0 macpost |

File folder containing MACPOST files required for MAC/GMC 4.0 results data post-processing using the MSC/PATRAN software package |

|

0 matlab |

File folder containing the MATLAB source files required for MAC/GMC 4.0 results data post-processing using the MATLAB software package |

It is recommended that the user create the directory “mac4” on their personal computer running the Microsoft WindowsÓ operating system and copy the entire contents of the cd to this directory. If disk drive space is at a premium, the contents of the “manuals” and “documents” folders can be omitted and the user can employ the cd when viewing the documentation contained in these folders. Note that, in order to read the documentation files provided in the “manuals” and “documents” folders, the user will need the Adobe AcrobatÓ Reader software installed on his/her computer. This software can be downloaded for free from:

http://www.adobe.com/products/acrobat/readstep.html

Executing MAC/GMC 4.0 Problems

The MAC/GMC 4.0 executable file (mac4.exe) is a DOS executable file intended to be executed through Microsoft WindowsÓ (NT, 2000, XP) at the command prompt. In order to execute a MAC/GMC 4.0 problem, at the command prompt, in the directory containing the executable, type:

mac4 in_name out_name

where,

|

in_name |

MAC/GMC 4.0 input file name |

|

out_name |

MAC/GMC 4.0 output file name (Optional) |

The code will look for the input file with the specified in_name and a “.mac” extension, so the specified in_name should not include an extension. The out_name specification is optional. If out_name is omitted, the code will use the specified input file name and write output to the file in_name.out. If out_name is specified and does not have an extension, the code will write output to the file out_name.out. Finally, if out_name is specified and does have an extension, the code will write output to the file out_name with the specified extension. If the desired input and output file locations are different than the current working directory, the directory path can be added to the specified in_name and out_name.

Example: Execute MAC/GMC 4.0 using the input file “example_1a.mac” located in the “mac4” directory, write output to the file “example_1a.out” located in the “mac4” directory.

C:\mac4>mac4 example_1a

Example: Execute MAC/GMC 4.0 using the input file “example_1a.mac” located in the “mac4” directory, write output to the file “test.out” located in the “mac4” directory.

C:\mac4>mac4 example_1a test

In the two example cases above, the following is written to the screen:

+--------------------------------------------------------------+

+ Micromechanics Analysis Code +

+ with +

+ Generalized Method of Cells +

+ +

+ MAC/GMC +

+ +

+ Version 4.0 +

+ +

+ *** WARNING *** +

+ No warranties are granted regarding the results of this code +

+ This code is export controlled by the U.S. government +

+--------------------------------------------------------------+

**** Checking Input File ****

> Input file name: c:\mac4\example_1a.mac

---> 0 Error(s) Detected <---

*** Determining Effective Properties ***

***************************

*** EXECUTION COMPLETED ***

***************************

Execution Time: 0.016 second(s)

As the above text indicates, MAC/GMC 4.0 performs a self-diagnostic “prescan” step prior to executing a given problem. During this prescan, the input file is checked for errors. If errors are detected, execution of the problem will not be completed, and a description of the detected errors will be written to the output file.

The MAC/GMC 4.0 input, output, and results data files can be viewed and edited with any standard ASCII file editor (such as Microsoft NotePad or Microsoft WordPad). Alternatively, MAC/GMC 4.0 can be set up to execute within a programming environment, such as Microsoft Visual Workspace. The best way to do this is to compile and link the MAC/GMC 4.0 library file and the user-defined subroutines within the programming environment, as described in the next section. The MAC/GMC 4.0 files can then be conveniently manipulated within the utilized programming environment.

Using User-Defined Subroutines with MAC/GMC 4.0

The MAC/GMC 4.0 static library file, along with the three MAC/GMC 4.0 user-defined subroutines, are included on the MAC/GMC 4.0 distribution cd in the “library” file folder. The contents of the “library” folder are:

|

mac4.lib |

MAC/GMC 4.0 static library file

|

|

usrformde.F90 |

MAC/GMC 4.0 user-defined FORTRAN 90 source file for determining constituent material elastic stiffness matrices from user-defined elastic constants (called when usrmat.F90 is employed) |

|

usrfun.F90 |

MAC/GMC 4.0 user-defined FORTRAN 90 source file for determining constituent material properties from a user-defined function of temperature or other variable |

|

usrmat.F90 |

MAC/GMC 4.0 user-defined FORTRAN 90 source file for determining inelastic strain and state variable increments from a user-defined inelastic constitutive model (material properties can be taken from the input file, the external material database, or the usrfun.F90 routine) |

In order to generate a MAC/GMC 4.0 executable file from these four files, the .F90 source files must be compiled and linked with the mac4.lib static library file using an appropriate Microsoft WindowsÓ (NT, 2000, XP) FORTRAN 90 compiler. MAC/GMC 4.0 was developed using the Compaq Visual Fortran product (v. 6.6), and it is thus recommended that this product be used. For information on this product, see: http://www.compaq.com/fortran/

The procedure for creating the MAC/GMC 4.0 executable from the four files above within Compaq Visual Fortran involves:

1) Create new fortran console application project:

a) Click “File” ® “New” ® “Projects” Tab ® select “Fortran Console Application”

® specify Location (directory path) and Project name and click “OK”

b) Select “An empty project” to create, click “Finish” and click “OK”

2) Add files to the project:

a) Click “Project” ® “Add to Project” ® “Files”

b) Select the MAC/GMC 4.0 static library file and the three user defined source files

listed above from the appropriate directory and click “OK”

3) Choose “Release” configuration to maximize execution speed

a) Click “Build” ® “Set Active Configuration …”

b) Select “… Win32 Release” and click “OK”

4) Build (compile and link) the executable

a) Click “Build” ® “Build project_name”

b) Alternatively, just hit F7 on the keyboard

This procedure will build an executable MAC/GMC 4.0 file in the “Release” directory. If a debug version is desired (which will allow the debugging of the user-defined subroutines only), the active configuration can be set to “Debug”.

To execute MAC/GMC 4.0 problems using this executable file from within the Compaq Visual Fortran environment:

1) Click “Project” ® “Settings”

2) Make sure that on the left the “Settings For:” box has the appropriate configuration listed and that the project name (rather than one of the source files or the library file) is highlighted.

3) On the right, choose the “Debug” tab

4) Under “Program arguments:”, type: in_name out_name (as you would after typing “mac4” at for execution via the DOS command prompt) and click “OK”

5) Select “Build” ® “Execute …” to run the code. (Alternatively hit the ! toolbar button)

Note that the MAC/GMC 4.0 input, output, and data results files can be viewed and edited within the Compaq Visual Fortran environment. The user-defined FORTRAN 90 source files can also be edited within this environment. It is important for the user to realize that the three provided user-defined FORTRAN 90 source files contain code that is used to demonstrate the MAC/GMC 4.0 user-defined capabilities. These same three subroutines are complied and linked into the MAC/GMC 4.0 distribution executable file (mac4.exe). If users wish to employ their own code in the user-defined subroutines, this code must be placed in the three user-defined FORTRAN 90 source files, and these files must be compiled and linked to the MAC/GMC 4.0 static library file (see procedure above). It is the user’s responsibility to ensure that his code is functioning properly and that his code is actually being utilized during execution rather than the demonstration code distributed in the three user-defined FORTRAN 90 source files. Note that a message is written to the screen when the distributed (default) versions of the user-defined subroutines are called. It is recommended that the user write a similar message to the screen to serve as notification that the intended subroutine is being called.

Format of the MAC/GMC 4.0 Input File

The remainder of this Keywords Manual deals with the specific input requirements of the MAC/GMC 4.0 input file to execute analyses of composite materials and laminates. This input file is an ASCII file that can be edited with any standard ASCII file editor. The first line of the input file is always interpreted as a title line. The remainder of the input file is divided into a number of keywords, which are placed on their own line in the file and are preceded by the asterisk character (*). A number of input lines follows each keyword, and each line contains specifier words, followed by an “=” sign. The input data read by the code then follows the “=” sign. An example of a MAC/GMC 4.0 input file is:

MAC/GMC 4.0 Example 1a - graphite/epoxy effective properties

*CONDUCTIVITY

NTEMP=1 TEMP=21.

*CONSTITUENTS

NMATS=2

# -- Graphite fiber

M=1 CMOD=6 MATID=U MATDB=1 &

EL=388.2E9,7.6E9,0.41,0.45,14.9E9,-0.68E-6,9.74E-6

K=500.,10.

# -- Epoxy matrix

M=2 CMOD=6 MATID=U MATDB=1 &

EL=3.45E9,3.45E9,0.35,0.35,1.278E9,45.E-6,45.E-6

K=0.19,0.19

*RUC

MOD=2 ARCHID=1 VF=0.65 F=1 M=2

NPL=-1

*END

This MAC/GMC 4.0 input file contains five keywords (highlighted in bold). In addition, the MAC/GMC 4.0 input file recognizes the following two special characters:

|

# |

Placed at the start of a line, makes the line a comment (which is ignored by the code) |

|

& |

Placed at the end of a line, serves as a continuation character and causes the code to treat the next line as part of the same line. |

These two special characters are very important as the the line on which the data specifiers are located within the MAC/GMC 4.0 input file is important. That is, examining a portion of the example input file given above,

# -- Graphite fiber

M=1 CMOD=6 MATID=U MATDB=1 &

EL=388.2E9,7.6E9,0.41,0.45,14.9E9,-0.68E-6,9.74E-6

K=500.,10.

The specifiers MATID=, MATDB=, and EL= are all on the same line (due to the presence of the “ &” continuation character), but the specifier K= is on its own line. If the correct input file format is not followed, the code will not execute and the errors detected within the input file will be described in the output file.

Finally, the order of the keywords in the input file is unimportant. The order of the specifiers on a particular line is also unimportant. As mentioned above, however, the order of the specifiers that are on different lines under a particular keyword is important. Despite the freedom to place the keywords and specifiers on a particular line in any order, this manual presents a logical suggested order for both. It is recommended that the user follow this order for the sake of logic and clarity.

The first section of the MAC/GMC 4.0 keywords involves the flag-type keywords. These three keywords are like switches that tell the code whether or not to perform certain analyses or do certain things. Like all keywords, they may be placed anywhere within the MAC/GMC 4.0 input file, but it is recommended that they be placed at the beginning of the file.

The three MAC/GMC input file keywords covered in this section are:

*CHECK ® Causes code only to check the input file without executing.

*CONDUCTIVITY ® Causes code to calculate effective thermal conductivities.

*ELECTROMAG ® Indicates that code execution will involve electromagnetic (smart) analysis.

It should be noted that if *CONDUCTIVITY is specified, there are additional input requirements for and restrictions on the constituent materials (specified with *CONSTITUENTS). Similarly, if *ELECTROMAG is specified, additional input requirements are associated with the constituent materials (specified with *CONSTITUENTS), the repeating unit cell or laminate (specified with *RUC or *LAMINATE), and the applied mechanical loading (specified with *MECH).

*CHECK: Check input file for errors

Purpose:

Specify that MAC/GMC 4.0 should only check the input file for errors and then stop. The code will not execute an analysis or generate any results.

Usage:

*CHECK

Example:

*CHECK

Associated MAC/GMC 4.0 Example Problem(s):

None

Notes:

1) MAC/GMC 4.0 always performs a “prescan” of the input file in order to check the data for errors and determine array dimensions for dynamic memory allocation. The *CHECK option stops the code after the prescan is complete.

2) There are some input data inconsistencies that cannot be detected during the prescan. Such errors will not be detected using the *CHECK option, but will be detected during analysis execution, causing the code to stop.

*CONDUCTIVITY: Effective thermal conductivities

Purpose:

Specify that MAC/GMC 4.0 should determine effective thermal conductivity components at the specified temperatures.

Usage:

*CONDUCTIVITY

NTEMP=ntemp TEMP=T(1),T(2),…,T(ntemp)

|

Name |

Definition |

|

ntemp |

Number of temperatures at which to calculate effective thermal conductivities |

|

T(i) |

Temperatures at which to calculate effective thermal conductivities |

Example:

*CONDUCTIVITY

NTEMP=3 TEMP=21.,200.,500.

Associated MAC/GMC 4.0 Example Problem(s):

Example 1a

Notes:

1) MAC/GMC 4.0 determines the three effective thermal conductivity components (in the three Cartesian coordinate directions) of a GMC repeating unit cell (RUC) at the specified temperatures as a separate pre-step. This is done prior to determination of the effective thermo-elastic properties and application of the simulated loading. The effective thermal conductivities are printed to the output file and then no longer stored or used by the code.

2) If the *CONDUCTIVITY keyword is specified, two thermal conductivity components (axial and transverse) must be specified for each constituent material read by MAC/GMC 4.0 (see Section 2, *CONSTITUENTS). Further, the material properties of the constituents must be user-defined (MATID=U).

3) The *CONDUCTIVITY keyword is only compatible with repeating unit cell analysis (*RUC), not laminate analysis (*LAMINATE).

4) The effective thermal conductivities are calculated based on the assumption that all constituent materials are (at most) transversely isotropic (in terms of their local thermal conductivities) and that their plane of isotropy is the x2-x3 plane in global RUC coordinates.

Additional Information:

MAC/GMC 4.0 Keywords Manual Section 2 (*CONSTITUENTS)

*ELECTROMAG: Electromagnetic analysis

Purpose:

Specify that MAC/GMC 4.0 should perform coupled thermo-electro-magneto-elasto-visco-plastic analysis.

Usage:

*ELECTROMAG

Example:

*ELECTROMAG

Associated MAC/GMC 4.0 Example Problem(s):

Example 7b, Example 7c

Notes:

1) Unlike determination of the effective thermal conductivities, electromagnetic analysis is tightly coupled within the MAC/GMC 4.0 formulation. Field variables associated with the thermo-electro-magnetic effects are stored and tracked during the MAC/GMC 4.0 execution and simulated electro-magnetic loading must be applied.

2) If the *ELECTROMAG keyword is specified, each constituent material read by MAC/GMC 4.0 must include the electromagnetic specifier: EM=1 indicates that the constituent material has electromagnetic material parameters associated with it; EM=0 indicates that the constituent material does not have electromagnetic material parameters associated with it (see Section 2, *CONSTITUENTS). For constituent materials with EM=1, electromagnetic material parameters must be specified, the material’s thermo-mechanical material properties must be user-defined (MATID=U), and the arbitrary transversely isotropic elastic constitutive model must be employed (CMOD=9).

3) Electromagnetic analysis may be performed for both repeating unit cell analysis (*RUC) and laminate analysis (*LAMINATE). However, the electromagnetic materials may only be part of triply periodic GMC RUCs. That is, if RUC analysis is specified, triply periodic GMC must be employed (MOD=3). If laminate analysis is specified, any layer that is electromagnetic (i.e., contains electromagnetic constituent materials) must employ triply periodic GMC (MOD=3).

4) In the case of electromagnetic laminate analysis (*LAMINATE), each layer must include the electromagnetic specifier: EM=1 indicates that the layer is electromagnetic (see Section 3, *LAMINATE).

5) Because electric and magnetic loading terms must be specified in the case of electromagnetic analysis, the arbitrary loading option (LOP=99) must be employed. The electromagnetic loading history is specified as mechanical loading components 7 – 12 (see Section 4, *MECH).

Additional Information:

MAC/GMC 4.0 Keywords Manual Section 2 (*CONSTITUENTS)

MAC/GMC 4.0 Keywords Manual Section 3 (*LAMINATE)

MAC/GMC 4.0 Keywords Manual Section 4 (*MECH)

MAC/GMC 4.0 Theory Manual Section 2.2.2

This section deals with two keywords related to the constituent materials that will form the repeating unit cell or laminate to be analyzed by MAC/GMC 4.0. These keywords are used to provide the code with the constituent material properties that will occupy the subcells in the analyzed repeating unit cell (RUC) or repeating unit cells that represent each ply of the laminate. Then, using keywords described in Section 3, the RUC is constructed using subcells, which contain some or all of the constituent materials. If the MAC/GMC 4.0 problem involves a laminate, the laminate is constructed of layers, each of which is represented by an RUC. The RUC for each layer is then constructed of subcells containing the constituent materials. Because the constituent materials always occupy subcells within an RUC, they can also be thought of as subcell materials. However, the subcell materials are not necessarily elastic or isotropic. MAC/GMC 4.0 handles a wide range of material visco-elasto-plastic material behavior and material anisotropy on the level of the subcell.

The two MAC/GMC 4.0 input file keywords covered in this section are:

*MDBPATH ® Specifies name and location of the external material database file.

*CONSTITUENTS ® Specifies the properties of constituent materials that will occupy subcells.

As one might expect, there are several ways in which MAC/GMC 4.0 can obtain the material properties for the constituent materials. These include:

1) Reading the properties directly from the MAC/GMC 4.0 input file.

2) Obtaining the properties from the internal MAC/GMC 4.0 material database.

3) Reading the properties from a user’s personal external material database file.

4) Obtaining the properties from a user-defined subroutine that calculates them based on a specified function.

In addition, different material properties are required for different analysis types and constitutive models. For example, if the user indicates that effective thermal conductivities should be calculated by the code (by including *CONDUCTIVITY in the input file), the thermal conductivities of the constituent materials must be specified in *CONSTITUENTS. Similarly, if the user chooses an inelastic constitutive model for a particular constituent material rather than a linear elastic constitutive model, material parameters for the particular inelastic constitutive model must be specified in addition to the material elastic constants. Because of this specialization of the constitutive material properties for many of the different problems that MAC/GMC 4.0 can solve, the data specification associated with the *CONSTITUENTS keyword is also quite specific compared to the other input parameters associated with the problem. As such, the part of this section dealing with the *CONSTITUENTS keyword is the longest and most involved component of this manual.

It is important to realize that the employed constituent material property units must be consistent. That is, all constituent materials that comprise an RUC or laminate must employ the same units. The units of the material properties within the MAC/GMC 4.0 internal material database are given in Table 2.2. Both ksi and MPa are used for the material property stress (and stiffness) unit. The time unit for all material properties is seconds, the temperature unit is °C, and the strain values are unitless (as opposed to %). Note also that any applied loading should be specified in units consistent with the material property units.

*MDBPATH: External material database file & location

Purpose:

Specify the name and path to an external material database file.

Usage:

*MDBPATH

PATH=mat_path NAME=mat_name

|

Name |

Definition |

|

mat_path1 |

Computer directory path to the external material database file (Optional) |

|

mat_name |

Name of the external material database file with extension |

Examples:

*MDBPATH

NAME=sample_material_database.mat

*MDBPATH

PATH=c:\mac4\mat_db\ NAME=sample_material_database.mat

Associated MAC/GMC 4.0 Example Problem(s):

Example 2h

Notes:

1) If the optional PATH=mat_path is omitted, the code will look for the external material database file in the same directory as the input file.

2) A sample external material database file, sample_material_database.mat, is distributed with MAC/GMC 4.0. This sample file is used in Example Problem 2h. A print out of this sample file is given in the Appendix of this manual.

3) The format of the external material database file is similar to the user-defined material property input format employed when the properties are specified directly in the input file. The specifics of the external material database file format are discussed under the *CONSTITUENTS keyword in the present section of this manual.

4) To choose a particular material from the external material database file, specific input is required under *CONSTITUENTS in order to specify the name of the material from the external material database file and that the code should look for the particular material in the external database file (see *CONSTITUENTS in the present section of this manual).

5) MAC/GMC 4.0 does not read in and store all constituent materials in the external material database file. The code only reads and stores the materials specified under *CONSTITUENTS. Thus, requirements that apply to all constituent materials only apply to those that are actually read from the external material database file. For example, electromagnetic analysis requires that all constituent materials have the electromagnetic specifier (EM=) included. If using an external material database, this requirement would not apply to every material appearing in the external material database file. It would only apply to those read by MAC/GMC 4.0 as specified under *CONSTITUENTS in the particular input file being employed.

Additional Information:

MAC/GMC 4.0 Keywords Manual Section 2 (*CONSTITUENTS)

*CONSTITUENTS: Constituent (subcell) materials

P *CONSTITUENTS is a required keyword P

Purpose:

Specify the constituent material constitutive models and material properties that will be read and stored by MAC/GMC 4.0. The local constitutive models supported by MAC/GMC 4.0 are listed in Table 2.1. Each is described in detail in the MAC/GMC 4.0 Theory Manual Section 4.

Table 2.1 Constituent material constitutive models supported by MAC/GMC 4.0.

|

cmod |

Model |

|

1 |

Bodner-Partom viscoplastic model |

|

2 |

Modified (non-isothermal) Bodner-Partom viscoplastic model |

|

3 |

Robinson transversely isotropic viscoplastic model |

|

4 |

Isotropic GVIPS model |

|

6 |

Standard elastic model (transversely isotropic with RUC x2-x3 plane of isotropy) |

|

7 |

Transversely isotropic GVIPS model |

|

9 |

Transversely isotropic elastic model (arbitrary specified plane of isotropy) |

|

10 |

Freed-Walker viscoplastic model |

|

11 |

Robinson isotropic viscoplastic model for NARloy Z |

|

15 |

Anisotropic elastic model |

|

21 |

Classical incremental (rate-independent) plasticity model |

|

22… |

Multimechanism visco-elasto-plastic GVIPS model |

|

30 |

Graesser - Cozzarelli - Witting shape memory alloy (SMA) model |

|

99 |

User-defined constitutive model (requires compilation of user code in usrmat.F90 and usrformde.F90 and linking with the MAC/GMC 4.0 library file mac4.lib) |

… Non-U.S. government users may require an additional software license to use this constitutive model

The material information specified under *CONSTITUENTS has many special cases based on the options chosen by the user and can become somewhat complicated. As such, the description for this keyword has been written in outline form in order to present the input requirements as simply as possible. Each outline heading has its own Usage description and Examples. The Notes have been consolidated and placed at the end of each capital lettered section. The outline format for the *CONSTITUENTS keyword is:

I. Properties taken from the internal material properties database (matid ¹ U)

II. User-defined material properties (matid = U)

A. Material properties read directly from the input file (matdb = 1)

1. Standard constitutive models (cmod¹15, cmod¹99)

a) Temperature-independent material properties

b) Temperature-dependent material properties

2. Special cases

a) Internal anisotropic constitutive model (cmod=15)

i) Temperature-independent material properties

ii) Temperature-dependent material properties

b) User-defined constitutive model (cmod=99)

i) Temperature-independent material properties

ii) Temperature-dependent material properties

B. Material properties determined from a user-defined function (matdb = 2)

C. Material properties read from external material database file (matdb = 3)

III. Electromagnetic (smart) material properties

A. Temperature-independent material properties

B. Temperature-dependent material properties

I. Internal material properties database (matid ¹ U)

Usage:

*CONSTITUENTS

NMATS=nmats

M=matnum CMOD=cmod TREF=tref MATID=matid D=d1,d2,d3

M=matnum CMOD=cmod TREF=tref MATID=matid D=d1,d2,d3

.

.

.

® Repeated nmats times

|

Name |

Definition |

|

nmats |

Number of constituent materials specified |

|

matnum |

Material number (data following M=matnum is associated with material number matnum) numbered sequentially |

|

cmod |

Constitutive model identification number (see Table 2.1) |

|

tref 1,2 |

Reference temperature for material (Special Case) |

|

matid |

Material i.d. letter, which indicates location of material parameters = A-H ® Internal material database (see Table 2.2) = U ® User-defined material properties |

|

d1,d2,d3 3 |

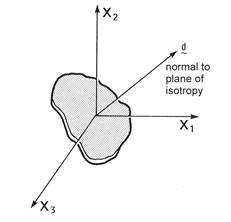

Components of vector normal to the plane of transverse isotropy (Special Case) (see Figure 2.1) |

Example:

*CONSTITUENTS

NMATS=4

M=1 CMOD=1 MATID=C

M=2 CMOD=6 TREF=650. MATID=B

M=3 CMOD=9 MATID=A D=0.,0.,1.

M=4 CMOD=21 MATID=F

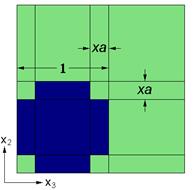

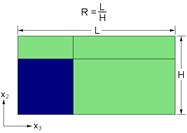

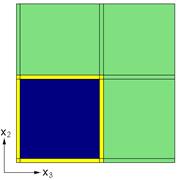

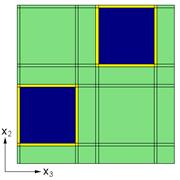

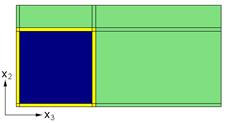

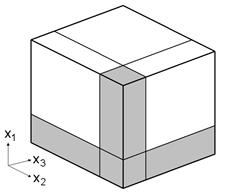

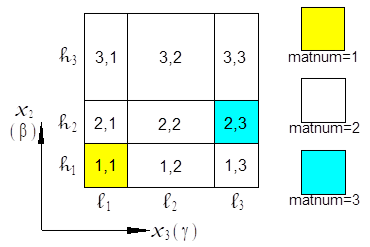

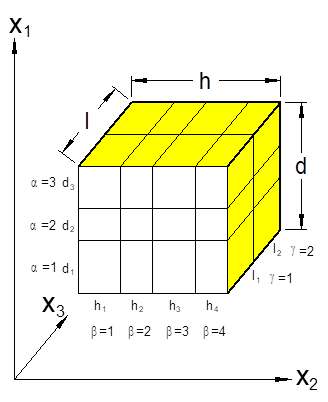

Figure 2.1 Definition of the d vector for local transverse isotropy.

Associated MAC/GMC 4.0 Example Problem(s):

Example 1c-d, Example 2a-d, Example 3a-i, Example 4a-d, Example 4f-h, Example 5e-f, Example 6a-c, Example 7a (see Table 2.2)

Notes:

1) TREF=tref is only required in the special case when the code cannot determine at what temperature the material properties should be taken. This special case occurs when:

· Thermal loading is not specified (*THERM omitted)

– AND –

· Material properties are taken from the internal material database (matid ¹ U)

– OR –

Material properties are user-defined (matid = U) – AND – temperature-dependent

2) In all other cases TREF=tref is optional.

Warning: Specifying TREF=tref will override the temperature dependence and cause the code to employ temperature-independent material properties for the material taken at the temperature tref.

3) D=d1,d2,d3 is only required in the special case when the specified material constitutive model is one that admits arbitrary local transverse isotropy. This occurs when:

cmod=3 – OR – cmod=7 – OR – cmod=9

Additional Information:

MAC/GMC 4.0 Keywords Manual Section 4 (*SOLVER)

MAC/GMC 4.0 Theory Manual Section 4

Table 2.2 MAC/GMC 4.0 constitutive models and internal material property database. Numerical values for the material properties can be obtained from the MAC/GMC output file.

|

Model |

matid |

Material |

Stress Units* |

Temperature Dependent? |

Example Problem(s) |

|

|

|

|

|

|

|

|

Bodner-Partom (CMOD=1) |

A |

Aluminum (2024-T4) |

MPa |

Yes |

2a |

|

B |

Aluminum (2024-0) |

MPa |

Yes |

2a |

|

|

C |

Aluminum (6061-0) a |

MPa |

Yes |

2a,3c |

|

|

D |

Aluminum (6061-0) b |

MPa |

Yes |

2a |

|

|

E |

Aluminum (pure) |

MPa |

Yes |

2a |

|

|

F |

Titanium (pure) |

MPa |

No |

2a |

|

|

G |

Copper |

MPa |

No |

2a |

|

|

U |

User-Defined |

– |

– |

2e,2f,2h |

|

|

|

|

|

|

|

|

|

Modified Bodner-Partom (CMOD=2) |

A |

Ti-21S |

MPa |

Yes |

2b |

|

U |

User-Defined |

– |

– |

– |

|

|

|

|

|

|

|

|

|

Robinson Transversely Isotropic Viscoplastic (CMOD=3) |

A |

Kanthal |

ksi |

No (600° C) |

– |

|

B |

FeCrAlY |

ksi |

Yes |

– |

|

|

C |

35% Tungsten/Kanthal Composite |

ksi |

No (600° C) |

– |

|

|

U |

User-Defined |

– |

– |

– |

|

|

|

|

|

|

|

|

|

Isotropic GVIPS (CMOD=4) |

A |

Ti-21S |

ksi |

Yes |

1c,1d,2b,3a,3b,3d-i,4a-d,4f-h,5e, 5f,6a-c,7a |

|

U |

User-Defined |

– |

– |

2e,3b |

|

|

|

|

|

|

|

|

|

Standard Linear Elastic (CMOD=6) |

A |

Boron Fiber |

MPa |

No |

3c |

|

B |

SiC (SCS-6) Fiber |

MPa |

Yes |

– |

|

|

C |

Tungsten Fiber |

MPa |

No |

– |

|

|

D |

Boron Fiber |

ksi |

No |

3a,3b |

|

|

E |

SiC (SCS-6) Fiber |

ksi |

Yes |

1d,3a,3b,3d-i,4a-d,4f-h, 5e,5f,6-c,7a |

|

|

F |

Tungsten Fiber |

ksi |

No |

– |

|

|

U |

User-Defined |

– |

– |

1a,1b,2e,2f,2h,4e,5a-d, 7d,7e |

|

|

|

|

|

|

|

|

|

Transversely Isotropic GVIPS (CMOD=7) |

A |

Ti-6-4 |

ksi |

Yes |

– |

|

U |

User-Defined |

– |

– |

– |

|

|

|

|

|

|

|

|

|

Transversely Isotropic Elastic (CMOD=9) |

A |

T50 Graphite |

MPa |

No |

– |

|

B |

T300 Graphite |

MPa |

No |

– |

|

|

C |

P100 Graphite |

MPa |

Yes |

– |

|

|

D |

T50 Graphite |

ksi |

No |

– |

|

|

E |

T300 Graphite |

ksi |

No |

– |

|

|

F |

P100 Graphite |

ksi |

Yes |

– |

|

|

U |

User-Defined |

– |

– |

7b-e |

Table 2.2 (continued)

|

|

|

|

|

|

|

|

Freed-Walker (CMOD=10) |

A |

Copper |

MPa |

Yes |

– |

|

B |

NARloy Z |

MPa |

Yes |

– |

|

|

U |

User-Defined |

– |

– |

– |

|

|

|

|

|

|

|

|

|

Robinson Isotropic (CMOD=11) |

A |

NARloy Z |

MPa |

Yes |

– |

|

U |

User-Defined |

– |

– |

– |

|

|

|

|

|

|

|

|

|

Anisotropic Elastic (CMOD=15) |

U |

User-Defined |

– |

– |

7e |

|

|

|

|

|

|

|

|

Classical Incremental Plasticity (CMOD=21) |

A |

Copper (bilinear) |

MPa |

Yes |

2c |

|

B |

Ti-24-11 (bilinear) |

MPa |

Yes |

2c |

|

|

C |

Ti-15-3 (point-wise) |

MPa |

Yes |

2c |

|

|

D |

Ti-24-11 (point-wise) |

MPa |

Yes |

2c |

|

|

E |

Copper (bilinear) |

ksi |

Yes |

– |

|

|

F |

Ti-24-11 (bilinear) |

ksi |

Yes |

– |

|

|

G |

Ti-15-3 (point-wise) |

ksi |

Yes |

– |

|

|

H |

Ti-24-11 (point-wise) |

ksi |

Yes |

– |

|

|

U |

User-Defined |

– |

– |

2e,2f |

|

|

|

|

|

|

|

|

|

Multimechanism GVIPS… (CMOD=22) |

A |

Ti-21S |

ksi |

Yes |

7a |

|

|

|

|

|

|

|

|

Shape Memory (CMOD=30) |

A |

NiTi |

MPa |

Yes |

2d |

|

B |

NiTi |

ksi |

Yes |

|

|

|

U |

User-Defined |

– |

– |

|

|

|

|

|

|

|

|

|

|

User-Defined (CMOD=99) |

U |

User-Defined |

– |

– |

2g,2h |

* Time units are all seconds, temperature units are all °C, strain is unitless

… Non-U.S. government users may require an additional software license to use this constitutive model

II. User-defined material properties (matid = U)

A. Material properties read directly from the input file (matdb = 1)

1. Standard constitutive models (cmod¹15, cmod¹99)

Usage:

a) Temperature-independent material properties

*CONSTITUENTS

NMATS=nmats

M=matnum CMOD=cmod TREF=tref MATID=matid MATDB=matdb &

EL=EA,ET,nA,nT,GA,aT,aA NP=np VI=vi(1),vi(2),…,vi(n) D=d1,d2,d3

K=kA,kT

.

.

.

® Repeated nmats times

b) Temperature-dependent material properties

*CONSTITUENTS

NMATS=nmats

M=matnum CMOD=cmod TREF=tref MATID=matid MATDB=matdb

NTP=ntp

TEM=T(1),T(2),…,T(ntp)

EA=EA(1), EA(2),…, EA(ntp)

ET= ET(1), ET(2),…, ET(ntp)

NUA=nA(1),nA(2),…,nA(ntp)

NUT=nT(1),nT(2),…,nT(ntp)

GA=GA(1),GA(2),…,GA(ntp)

ALPA=aA(1),aA(2),…,aA(ntp)

ALPT=aT(1),aT(2),…,aT(ntp)

NP=np

V1=V1(1), V1(2),…, V1(ntp)

V2=V2(1), V2(2),…, V2(ntp)

.

. ® Repeated n times, where n = number of visco-inelastic properties (see Table 2.3)

.

Vn=Vn(1), Vn(2),…, Vn(ntp)

KA=kA(1),kA(2) ,…,kA(ntp)

KT=kT(1),kT(2) ,…,kT(ntp)

D=d1,d2,d3

.

.

.

® Repeated nmats times

|

Name |

Definition |

|

nmats |

Number of constituent materials specified |

|

matnum |

Material number (data following M=matnum is associated with material number matnum) numbered sequentially |

|

cmod |

Constitutive model identification number |

|

tref 1,2 |

Reference temperature for material (Special Case) |

|

matid [=U] |

Material i.d. letter, which indicates location of material parameters = A-H ® Internal material database (see Table 2.2) = U ® User-defined material properties |

|

matdb [=1] |

Material database location: = 1 ® Material properties read from input file = 2 ® Material properties determined from user-defined function (usrfun.F90) = 3 ® Material properties read from external material database file |

|

EA,ET 3 |

Axial and transverse elastic (i.e., “Young’s”) modulus |

|

nA,nT 3 |

Axial and transverse Poisson ratios |

|

GA 3 |

Axial shear modulus |

|

aT,aA 3 |

Axial and transverse coefficients of thermal expansion (CTEs) |

|

np 4 |

Number of stress-strain points employed to characterize post-yield portion of the stress-strain curve for classical plasticity (Special Case) |

|

vi(1-n) 5 |

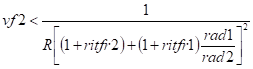

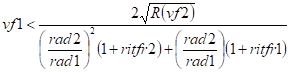

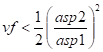

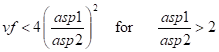

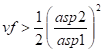

Visco-inelastic material properties (Special Case) n = number of visco-inelastic material

properties and is cmod dependent ( |

|

d1,d2,d3 6 |

Components of vector normal to the plane of transverse isotropy (Special Case) (see Figure 2.1) |

|

kA,kT 7 |

Axial and transverse thermal conductivities (Special Case) |

|

ntp |

Number of temperatures at which the material properties are specified |

|

T(i) |

Temperatures at which the material properties are specified |

|

EA(i) 3 |

Axial elastic (i.e., “Young’s”) modulus at input temperature number i |

|

ET(i) 3 |

Transverse elastic (i.e., “Young’s”) modulus at input temperature number i |

|

nA(i) 3 |

Axial Poisson ratio at input temperature number i |

|

nT(i) 3 |

Transverse Poisson ratios at input temperature number i |

|

GA(i) 3 |

Axial shear modulus at input temperature number i |

|

aA(i) 3 |

Axial coefficient of thermal expansion (CTEs) at input temperature number i |

|

aT(i) 3 |

Transverse coefficients of thermal expansion (CTEs) at input temperature number i |

|

Vj(i) 5 |

Visco-inelastic material property number j at input temperature number i (Special Case) |

|

kA(i) 6 |

Axial thermal conductivity at input temperature number i (Special Case) |

|

kT(i) 6 |

Transverse thermal conductivity at input temperature number i (Special Case) |

Table 2.3 Temperature-independent user-defined inelastic material property specification. See the MAC/GMC 4.0 Theory manual for details on the constitutive models and their parameters.

|

|

n |

Inelastic material property specification |

Plane of transverse isotropy specification |

|

Bodner-Partom (CMOD=1) |

6 |

VI = D0, Z0, Z1, m, n, q |

N/A |

|

Modified Bodner-Partom (CMOD=2) |

17 |

VI = D0, Z0, Z1, Z2, Z3, m1, m2, n, a1, a2, r1, r2, Dm1, Dm2, Dz1, Dz2, Dz3 |

N/A |

|

Robinson Transversely Isotropic Viscoplastic (CMOD=3) |

10 |

VI =

m, kT, R, H, n, m, b, h, w, |

D=d1,d2,d3 |

|

Isotropic GVIPS (CMOD=4) |

11 |

VI = m, k, Ra, B0, B1, n, p, q, k0, B0’, b |

N/A |

|

Standard Linear Elastic (CMOD=6) |

N/A |

N/A Elastic Only |

N/A |

|

Transversely Isotropic GVIPS (CMOD=7) |

10 |

VI = k, n, m, m, b, R, H, G0, w, h |

D=d1,d2,d3 |

|

Transversely Isotropic Elastic (CMOD=9) |

N/A |

N/A Elastic Only |

D=d1,d2,d3 |

|

Freed-Walker (CMOD=10) |

14 |

VI = A, C, n, Q,

Tm, Tt, d, f, h, l, D0,

|

N/A |

|

Robinson Isotropic (CMOD=11) |

9 |

VI = A, n, m, b, H, R, K2, K0, G0 |

N/A |

|

Anisotropic Elastic (CMOD=15) |

N/A |

N/A Elastic Only, Special Case – see below |

N/A |

|

Classical Plasticity (CMOD=21) |

np+1 |

NP=np VI = sy, s1, s2, … , snp, e1, e2, … , enp (sy is the yield stress and si,ei are stress-total strain pairs that characterize the post-yield response) |

N/A |

|

Multimechanism GVIPS (CMOD=22) |

N/A |

N/A Model not currently supported with user-defined properties |

N/A |

|

Shape Memory (CMOD=30) |

5 |

VI = fT, Y, a, a, n |

N/A |

|

User-Defined (CMOD=99) |

N/A |

N/A Special Case – see below |

N/A |

Examples:

a) Temperature-independent material properties

*CONSTITUENTS

NMATS=2

M=1 CMOD=6 MATID=U MATDB=1 &

EL=388.2E9,7.6E9,0.41,0.45,14.9E9,-0.68E-6,9.74E-6

K=500.,10.

M=2 CMOD=6 MATID=U MATDB=1 &

EL=3.45E9,3.45E9,0.35,0.35,1.278E9,45.E-6,45.E-6

K=0.19,0.19

*CONSTITUENTS

NMATS=5

M=1 CMOD=1 MATID=U MATDB=1 &

EL=9.53E3,9.53E3,0.33,0.33,3.58E3,21.06E-6,21.06E-6 &

VI=1.E4,49.,63.,300.,4.,1.

M=2 CMOD=9 MATID=U MATDB=1 &

EL=253.5E9,6.05E9,0.39,0.47,4.167E9,-0.4724E-6,26.63E-6 D=0.5,1.,0.

M=3 CMOD=4 MATID=U MATDB=1 &

EL=14009.,14009.,0.365,0.365,5131.5,5.862E-6,5.862E-6 &

VI=0.000999275,44.960,1.679E-07,2.494561E-05,0.05, &

3.3,1.8,1.35,0.85,3.0183E-7,0.001

M=4 CMOD=10 MATID=U MATDB=1 &

EL=0.1305E+06,0.1305E+06,0.36,0.36,0.4798E+05,0.165E-04,0.165E-04 &

VI=0.2000E+08,0.1300E+02,0.4500E+01,0.2000E+06,1082.85, &

404.85,0.3500E-01,0.5000E+00,0.4000E+02,0.6500E+01, &

0.1300E+00,0.1000E-01,0.1000E-06,0.7000E+00

M=5 CMOD=21 MATID=U MATDB=1 &

EL=10000.,10000.,0.326,0.326,3770.,12.00E-6,12.00E-6 &

NP=1 VI=5.08,13.1,0.15

b) Temperature-dependent material properties

*CONSTITUENTS

NMATS=2

M=1 CMOD=21 MATID=U MATDB=1

NTP=3

TEM=21.,400.,800.

EA=10000.,9000.,7300.

ET=10000.,9000.,7300.

NUA=0.326,0.351,0.345

NUT=0.326,0.351,0.345

GA=3771.,3331.,2714.

ALPA=12.00E-6,13.50E-6,22.72E-6

ALPT=12.00E-6,13.50E-6,22.72E-6

NP=3

V1=4.20,3.81,3.05

V2=6.13,4.77,3.69

V3=6.60,5.10,3.90

V4=13.1,9.70,5.10

V5=0.004,0.004,0.004

V6=0.01,0.01,0.01

V7=0.15,0.15,0.15

M=2 CMOD=1 MATID=U MATDB=1

NTP=2

TEM=18.,700.

EA=9.53E3,4.12E3

ET=9.53E3,4.12E3

NUA=0.41,0.41

NUT=0.41,0.41

GA=3.58E3,1.46E3

ALPA=21.06E-6,28.92E-6

ALPT=21.06E-6,28.92E-6

V1=1.E4,1.E4

V2=49.,49.

V3=63.,63.

V4=300.,300.

V5=4.,2.5

V6=1.,1.

Associated MAC/GMC 4.0 Example Problem(s):

a) Temperature-independent material properties

Example 1a, Example 1b, Example 2e, Example 3b, Example 7e

b) Temperature-dependent material properties

Example 2e, Example 4e, Example 5a, Example 5b, Example 5c, Example 5d

Additional Information:

MAC/GMC 4.0 Keywords Manual Section 4 (*SOLVER)

MAC/GMC 4.0 Theory Manual Section 4

2. Special cases

a) Internal anisotropic constitutive model (cmod=15)

Usage:

i) Temperature-independent material properties

*CONSTITUENTS

NMATS=nmats

M=matnum CMOD=cmod TREF=tref MATID=matid MATDB=matdb &

EL=C11,C12,C13,C14,C15,C16,C22,C23,C24,C25,C26,C33,C34,C35,C36,C44,C45,C46,C55,C56,C66, &

a11, a22, a33,a23,a13,a12

.

.

.

® Repeated nmats times

ii) Temperature-independent material properties

*CONSTITUENTS

NMATS=nmats

M=matnum CMOD=cmod TREF=tref MATID=matid MATDB=matdb

NTP=ntp

TEM=T(1),T(2),…,T(ntp)

C11=C11(1),C11(2),…,C11(ntp)

C12=C12(1),C12(2),…,C12(ntp)

C13=C13(1),C13(2),…,C12(ntp)

C14=C14(1),C14(2),…,C14(ntp)

C15=C15(1),C15(2),…,C15(ntp)

C16=C16(1),C16(2),…,C16(ntp)

C22=C22(1),C22(2),…,C22(ntp)

C23=C23(1),C23(2),…,C23(ntp)

C24=C24(1),C24(2),…,C24(ntp)

C25=C25(1),C25(2),…,C25(ntp)

C26=C26(1),C26(2),…,C26(ntp)

C33=C33(1),C33(2),…,C33(ntp)

C34=C34(1),C34(2),…,C34(ntp)

C35=C35(1),C35(2),…,C35(ntp)

C36=C36(1),C36(2),…,C36(ntp)

C44=C44(1),C44(2),…,C44(ntp)

C45=C45(1),C45(2),…,C45(ntp)

C46=C46(1),C46(2),…,C46(ntp)

C55=C55(1),C55(2),…,C55(ntp)

C56=C56(1),C56(2),…,C56(ntp)

C66=C66(1),C66(2),…,C66(ntp)

ALF1=a11(1),a11(2),…,a11(ntp)

ALF2=a22(1),a22(2),…,a22(ntp)

ALF3=a33(1),a33(2),…,a33(ntp)

ALF4=a23(1),a23(2),…,a23(ntp)

ALF5=a13(1),a13(2),…,a13(ntp)

ALF6=a12(1),a12(2),…,a12(ntp)

.

.

.

® Repeated nmats times

|

Name |

Definition |

|

nmats |

Number of constituent materials specified |

|

matnum |

Material number (data following M=matnum is associated with material number matnum) numbered sequentially |

|

cmod [=15] |

|

|

tref 1,2 |

Reference temperature for material (Special Case) |

|

Name |

Definition |

|

matid [=U] |

Material i.d. letter, which indicates location of material parameters = A-H ® Internal material database (see Table 2.2) = U ® User-defined material properties |

|

matdb [=1] |

Material database location: = 1 ® Material properties read from input file = 2 ® Material properties determined from user-defined function (usrfun.F90) = 3 ® Material properties read from external material database file |

|

Cij |

Stiffness matrix coefficients |

|

aij 3 |

CTE vector components (anisotropic materials can have 6 CTE components) |

|

ntp |

Number of temperatures at which the material properties are specified |

|

T(i) |

Temperatures at which the material properties are specified |

|

Cjk(i) |

Stiffness matrix component jk at input temperature number i |

|

ajk(i) 3 |

CTE component jk at input temperature number i |

Examples:

i) Temperature-independent material properties

*CONSTITUENTS

NMATS=1

M=1 CMOD=15 MATID=U MATDB=1 &

EL=6.677E9, 3.274E9, 4.843E9, 0., -0.1887E9, 0., &

6.662E9, 3.384E9, 0., 0.006711E9, 0., &

55.80E9, 0., -6.969E9, 0., &

2.625E9, 0., -0.1830E9, &

2.269E9, 0., &

1.613E9 &

43.74E-6, 39.04E-6, 4.043E-6, 0., 12.19E-6, 0.

ii) Temperature-dependent material properties

*CONSTITUENTS

NMATS=1

M=1 CMOD=15 MATID=U MATDB=1

NTP=2

TEM=23.,250.

C11=6.677E9,5.973E9

C12=3.274E9,2.931E9

C13=4.843E9,4.517E9

C14=0.,0.

C15=0.1887E9,0.1932E9

C16=0.,0.

C22=6.662E9,5.867E9

C23=3.384E9,3.023E9

C24=0.,0.

C25=-0.006711E9,0.008475E9

C26=0.,0.

C33=55.80E9,48.22E9

C34=0.,0.

C35=6.969E9,7.105E9

C36=0.,0.

C44=2.625E9,2.124E9

C45=0.,0.

C46=0.1830E9,0.1363E9

C55=2.269E9,2.123E9

C56=0.,0.

C66=1.613E9,1.444E9

ALF1=43.74E-6,46.75E-6

ALF2=39.04E-6,43.81E-6

ALF3=4.043E-6,5.241E-6

ALF4=0.,0.

ALF5=-12.19E-6,-16.45E-6

ALF6=0.,0.

Associated MAC/GMC 4.0 Example Problem(s):

Additional Information:

MAC/GMC 4.0 Keywords Manual Section 4 (*SOLVER)

b) User-defined constitutive model (cmod=99)

Usage:

i) Temperature-independent material properties

*CONSTITUENTS

NMATS=nmats

M=matnum CMOD=cmod TREF=tref MATID=matid MATDB=matdb NPE=npe NPV=npv &

EL=E(1),E(2),…,E(npe) ALP=αA,αT VI=V(1),V(2),…,V(npv)

K=kA,kT

.

.

.

® Repeated nmats times

ii) Temperature-dependent material properties

*CONSTITUENTS

NMATS=nmats

M=matnum CMOD=cmod TREF=tref MATID=matid MATDB=matdb

NPE=npe NPV=npv

NTP=ntp

TEM=T(1),T(2),…,T(ntp)

E1=E1(1), E1(2),…, E1(ntp)

E2= E2(1), E2(2),…, E2(ntp)

.

. ® Repeated npe times

.

Envp=Envp(1), Envp(2),…, Envp(ntp)

ALPA=aA(1),aA(2),…,aA(ntp)

ALPT=aT(1),aT(2),…,aT(ntp)

V1=V1(1), V1(2),…, V1(ntp)

V2=V2(1), V2(2),…, V2(ntp)

.

. ® Repeated npv times

.

Vnvp=Vnvp(1), Vnvp(2),…, Vnvp(ntp)

KA=kA(1),kA(2) ,…,kA(ntp)

KT=kT(1),kT(2) ,…,kT(ntp)

.

.

.

® Repeated nmats times

|

Name |

Definition |

|

nmats |

Number of constituent materials specified |

|

matnum |

Material number (data following M=matnum is associated with material number matnum) numbered sequentially |

|

cmod [=99] 9,10 |

Constitutive model identification number |

|

tref 1,2 |

Reference temperature for material (Special Case) |

|

matid [=U] |

Material i.d. letter, which indicates location of material parameters = A-H ® Internal material database (see Table 2.2) = U ® User-defined material properties |

|

matdb [=1] |

Material database location: = 1 ® Material properties read from input file = 2 ® Material properties determined from user-defined function (usrfun.F90) = 3 ® Material properties read from external material database file |

|

npe |

Number of elastic constants employed in user-defined constitutive model |

|

npv 4 |

Number of visco-inelastic constants employed in user-defined constitutive model |

|

E(1-npe) |

Elastic constants |

|

αA,αT |

Axial and transverse coefficients of thermal expansion (CTEs) |

|

V(1-npv) 4 |

Visco-inelastic constants |

|

kA,kT 7 |

Axial and transverse thermal conductivities (Special Case) |

|

Number of temperatures at which the material properties are specified |

|

|

T(i) |

Temperatures at which the material properties are specified |

|

Ej(i) |

Elastic material property number j at input temperature number i |

|

aA(i) |

Axial coefficient of thermal expansion (CTEs) at input temperature number i |

|

aT(i) |

Transverse coefficients of thermal expansion (CTEs) at input temperature number i |

|

Vj(i) 11 |

Visco-inelastic material property number j at input temperature number i |

|

kA(i) 7 |

Axial thermal conductivity at input temperature number i (Special Case) |

|

kT(i) 7 |

Transverse thermal conductivity at input temperature number i (Special Case) |

Examples:

i) Temperature-independent material properties

*CONSTITUENTS

NMATS=2

M=1 CMOD=99 MATID=U MATDB=1 NPE=2 NPV=2 &

EL=55.2E9,0.30 ALP=22.5E-6,22.5E-6 VI=1.5E-28,3.0

K=273.,273.

M=2 CMOD=99 MATID=U MATDB=1 NPE=2 NPV=6 &

EL=55.2E9,0.30 ALP=22.5E-6,22.5E-6 &

VI=1000.,103.42E6,103.42E6,1700.,10.,1.0

K=273.,273.

ii) Temperature-dependent material properties

*CONSTITUENTS

NMATS=1

M=1 CMOD=99 MATID=U MATDB=1

NPE=2 NPV=2

NTP=3

TEM=21.,350.,650.

E1=55.2E9,52.7E9,47.1E9

E2=0.30,0.30,0.30

ALPA=22.5E-6,23.4E-6,27.0E-6

ALPT=22.5E-6,23.4E-6,27.0E-6

V1=1.5E-28,1.5E-28,1.5E-28

V2=3.0,3.017,3.052

Associated MAC/GMC 4.0 Example Problem(s):

Example 2g

Additional Information:

MAC/GMC 4.0 Keywords Manual Appendix

Notes:

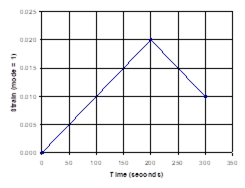

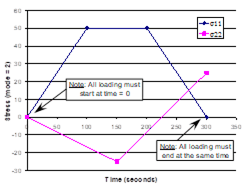

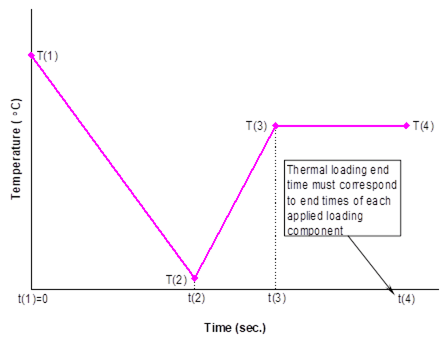

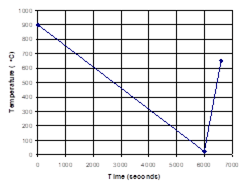

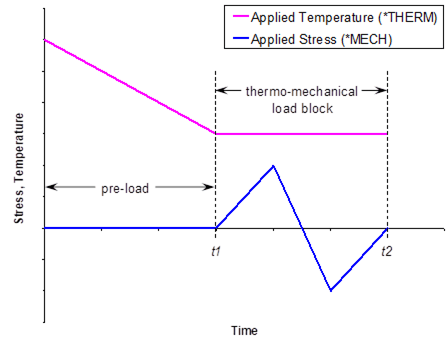

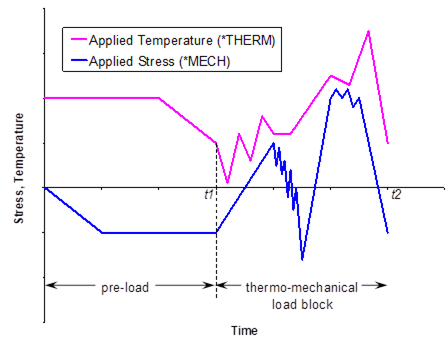

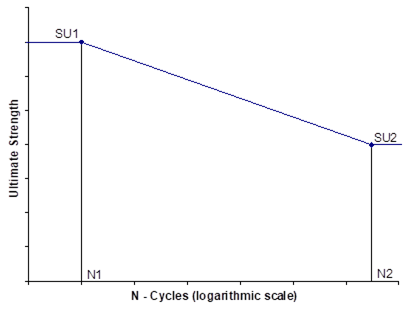

1) TREF=tref is only required in the special case when the code cannot determine at what temperature the material properties should be taken. This special case occurs when: